1 RAMELTEON

2TASIMELTEON

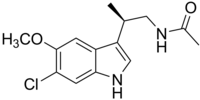

3 LY156735, TIK 301

4

5

6

1 RAMELTEON

RAMELTEON

ACN-S001714, ZINC00007031

- HSDB 7787

- Ramelteon

- Rozerem

- TAK-375

- UNII-901AS54I69

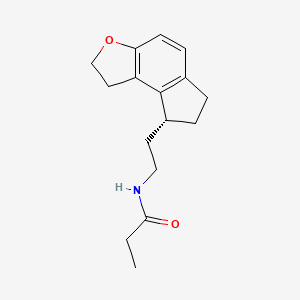

Molecular Formula: C16H21NO2 Molecular Weight: 259.34344

| CAS number | 196597-26-9 |

|---|

| (S)-N-[2-(1,6,7,8-tetrahydro-2H-indeno-[5,4-b]furan-8-yl)ethyl]propionamide |

(5)-N-[2-(l,6,7,8-tetrahydro-2H-indeno-[5,4-ό]furan-8- yl)ethyl]propionamide

| United States | US 6034239 | 1999-07-22 | expiry 2019-07-22 |

EP885210B1 , EP1792899A1 and J. Med Chem. 2002, 45, 4222-4239

NMR

- dmd.aspetjournals.org/content/suppl/…/Supplemental_Information.pptx

May 17, 2010 - Ramelteon NMR Assignments. COSY: Black Arrows. HMBC: Red Arrows. Figure S-1b. 1H NMR Spectrum of Ramelteon. Figure S-1c.

Ramelteon is the first in a new class of sleep agents that selectively binds to the melatonin receptors in the suprachiasmatic nucleus (SCN). It is used for insomnia, particularly delayed sleep onset. Ramelteon has not been shown to produce dependence and has shown no potential for abuse.

Ramelteon, marketed as Rozerem by Takeda Pharmaceuticals North America, is the first in a new class of sleep agents that selectively binds to the MT1 and MT2 receptors in the suprachiasmatic nucleus (SCN), instead of binding to GABA A receptors, such as with drugs like zolpidem,eszopiclone, and zaleplon. Ramelteon is approved by the U.S. Food and Drug Administration (FDA) for long-term use.

Ramelteon does not show any appreciable binding to GABAA receptors, which are associated with anxiolytic, myorelaxant, and amnesic effects.

Rozerem (ramelteon), FDA Approved 07.04.05, can be used for insomnia, particularly delayed sleep onset. Ramelteon has not been shown to produce dependence and has shown no potential for abuse, and the withdrawal and rebound insomnia that is typical with GABA modulators is not present in ramelteon. Some clinicians also use ramelteon for the treatment of Delayed sleep phase syndrome.

Ramelteon

RamelteonMechanism of action

Ramelteon is a melatonin receptor agonist with both high affinity for melatonin MT1 and MT2 receptors and selectivity over the MT3 receptor. Ramelteon demonstrates full agonist activity in vitro in cells expressing human MT1 or MT2 receptors, and high selectivity for human MT1 and MT2receptors compared to the MT3 receptor.[1]

The activity of ramelteon at the MT1 and MT2 receptors is believed to contribute to its sleep-promoting properties, as these receptors, acted upon by endogenous melatonin, are thought to be involved in the maintenance of the circadian rhythm underlying the normal sleep-wake cycle. Ramelteon has no appreciable affinity for the GABA receptor complex or for receptors that bind neuropeptides, cytokines, serotonin, dopamine, noradrenaline,acetylcholine, and opiates. Ramelteon also does not interfere with the activity of a number of selected enzymes in a standard panel.

The significance of ramelteon’s lack of affinity for the MT3 receptor is not clear, despite the manufacturer’s emphasis of this fact in commercial advertisements. The MT3 receptor appears almost exclusively in the gut and might not have any relationship to sleep or wakefulness.

The major metabolite of ramelteon, M-II, is active and has approximately one tenth and one fifth the binding affinity of the parent molecule for the human MT1 and MT2 receptors, respectively, and is 17 – 25-fold less potent than ramelteon in in vitro functional assays. Although the potency of M-II at MT1 and MT2 receptors is lower than the parent drug, M-II circulates at higher concentrations than the parent producing 20 – 100 fold greater mean systemic exposure when compared to ramelteon. M-II has weak affinity for the serotonin 5-HT2B receptor, but no appreciable affinity for other receptors or enzymes. Similar to ramelteon, M-II does not interfere with the activity of a number of endogenous enzymes.

All other known metabolites of ramelteon are inactive.

No published studies have indicated whether ramelteon, in humans, is more or less safe or effective than the hormone melatonin which it mimics; melatonin is much less expensive and is widely available over-the-counter in the US and Canada. The biological action of melatonin is similar to that of ramelteon. Ramelteon has been directly compared to melatonin in cats, and Ramelteon had a significant (3x) longer effect and had a more profound effect on the EEG of the sleeping cats.[2]

Introduction

ROZEREM (ramelteon) is an orally active hypnotic, chemically designated as (S)-N-[2- (l,6,7,8-tetrahydro-2H-indeno-[5,4-b]furan-8-yl)ethyl]propionamide, and contains one chiral center. The compound is produced as the (S)-enantiomer, with an empirical formula of C16H21N02, molecular weight of 259.34, and the following chemical structure (I):

(I) -Ramelteon

Ramelteon is used to help patients who have sleep-onset insomnia (difficulty falling asleep) to fall asleep more quickly. It is the first in a new class of sleep agents that selectively binds to the MT] and MT2 receptors in the suprachiasmatic nucleus (SCN), in a class of medications called melatonin receptor agonists with both high affinity for melatonin MT! and MT2 receptors and selectivity over the MT3 receptor. It works similarly to melatonin, a natural substance in the brain that is needed for sleep.

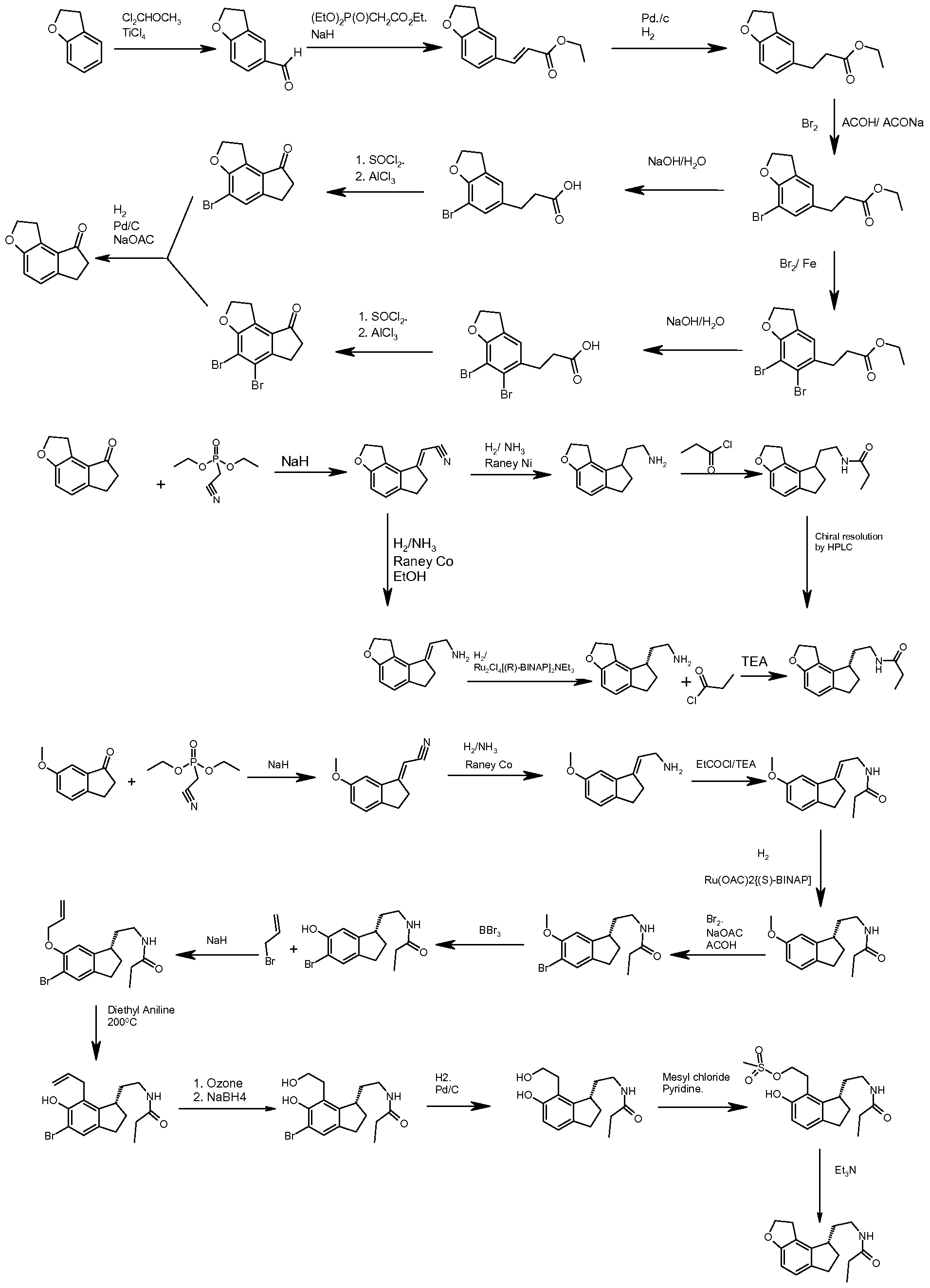

Ramelteon was first disclosed in European patent EP 885210, which also disclosed a process for synthesizing ramelteon, as shown in scheme 1 : Scheme 1

Ramelteon

The processes of the prior art suffer from many disadvantages, some of which result from the fact that they involve several steps.

For instance, in US patent US 6034239, which is related to EP 885210, there is disclosed a process for preparing an intermediate compound of Formula (IV), which involves conversion of diethylcyano methyl phosphonate in the presence of 60% sodium hydride. Disadvantages of this particular reaction include the need for the highly flammable and corrosive base sodium hydride, the use of toxic triethyl phosphate for the formation of diethylcyano methyl phosphonate (which also has a high boiling point), and low yield of 60%. Such disadvantages mean that the disclosed process is difficult to implement industrially or economically. A further problem associated with prior art preparation techniques is the formation of dimeric impurities at the nitrile reduction stage (i.e. where the intermediate of Formula (IV) is reduced). For instance, US 6034239 discloses reduction of (l,2,6,7-Tetrahydro-8H-indeno-[5,4- b]furan-8-ylidene)-acetonitrile of formula (IV) by means of H2 over Raney nickel in in a solvent medium of ethanol NH3 to provide compound of formula (IIA). The reaction is carried out by applying 5 kg of hydrogen pressure, which results in the formation of the byproduct and impurity Dimer A, which in turn affects the yield and purity of the product of formula (IIA).

Dimer A

Similarly, (l,2,6,7-Tetrahydro-8H-indeno-[5,4-b]furan-8-ylidene)-acetonitrile of formula (IV) may be reduced by means of H2 over Raney cobalt in a solvent medium of ethanol/ NH3 to afford compound of formula (IIB). The reaction, which is carried out by applying hydrogen pressure, is not selective, and results in the formation of the by-product and impurity Dimer B, which in turn affects the yield and purity of product of formula (IIB).

Dimer B

Repeated purifications are required to remove impurities such as Dimer A and B to obtain ramelteon having the desired purity, which results in the poor yield of ramelteon.

Several other approaches are also described in the literature to make ramelteon and related compounds in WO2006030739, WO208062468, WO2008106179, US 2010152468, WO2009106966 and WO2010/055481. However, all processes of the prior art for the preparation of ramelteon are cumbersome; the processes employ a plurality of reagents and involve multiple steps, which make the overall processes uneconomical. Therefore there is a need for a more economical, efficient and industrially suitable method of making ramelteon, whereby address the problems associated with prior art, some of which are discussed above.

Ramelteon is the active ingredient in trademarked ROZEREM®, and is approved by the United States Food and Drug Administration for the treatment of insomnia characterized by difficulty with sleep onset.

Different processes for preparing (S)-N-[2-(l,6,7,8-tetrahydro-2H-indeno-[5,4- b]furan-8-yl)ethyl]propionamide, i.e. ramelteon, are disclosed in US 6034239, JP 11080106, JP 11140073 and WO 2006/030739. U.S. Patent No. 6034239 describes the following processes for the preparation of ramelteon:

Japan Patent Publication No. 11080106 reports the following process for the preparation of ramelteon:

Ru(OCOCH3)[(R)-BI NAP] IOOatm H2/50 temp

BF3 DEE Complex

Japan Patent Publication no. 11140073 reports the following process for the preparation of an intermediate of ramelteon:

PCT Publication No. WO/2006/030739 reports the following process for the preparation of ramelteon:

POCI3/DMF (EtO)2P(O)CH2CO2Et Toluene NaH/Toluene

Purification in Ethanol water 95 7%

United States Patent No. 6,034,239 discloses the formation of chiral intermediates (S)-(- )-N-[2-(l,6,7,8,-tetrahydro-2H-indeno[5,4-b]furan-8-yl)ethylamine (sometimes referred to as compound S-2 or intermediate compound S-2) by the catalytic asymmetric hydrogenation of 2- (l,2,6,7,-tetrahydro-8H-indeno[5,4-b]furan-8-ylidene)ethylamine (compound 3 in the reaction scheme shown below) in the presence of a catalytic amount of BINAP-ruthenium complex in approximately 89% e.e. (enantiomeric excess). Following the catalytic reaction, the product is purified by preparing acid salts and acylated with propionyl chloride (compound 4 in the reaction scheme shown below) to obtain ramelteon (compound 1 in the reaction scheme shown below) in its pure (S) isomer form.

|S)*2

An alternate process for preparing ramelteon is disclosed in the Journal of Medicinal Chemistry, Vol. 45, pp. 4222-4239 (2002), wherein the exo double bond of intermediates (A) shown below was asymmetrically reduced using (S)-2, 2′-bis-(diphenylphosphino)-l, 1 ‘- binaphthyl (binap)-Ru complex as the catalyst to obtain the enantiomerically pure compound (B). Compound (B) is subsequently converted to ramelteon (1) through the intermediate steps of Claisen condensation, ozonolysis and cyclization.

m Both of the above processes uses expensive catalyst and give poor enantioselectivity. Additionally, these processes are expensive due to the need to perform multiple purifications steps in order to achieve an enantioselectivity of at least about 99% or greater of the desired isomer.

PCT Patent Publication No. WO 2008/062468 A2 discloses the following process for the preparation of ramelteon:

RAMELTEON

WO 2008/062468 teaches that separation of the enantiomers of intermediate (2) may be accomplished by: i) optical resolution of the racemic amine intermediate (2) by preparing acid salts with chirally pure acids; or ii) chromatographic techniques using chiral and/or achiral stationary phases for batch process, super critical or sub critical chromatography and/or continuous process chromatography. Although WO 2008/062468 mentions the possible use of optical resolution with chirally pure acids, there is no further teaching, discussion or disclosure of this method. WO 2008/062468 does, however, provide detailed descriptions of chromatographic methods for separating the isomers of intermediate compound (2). The disclosed chromatographic process suffers the following disadvantages:

• Preparative chromatography is time consuming & expensive;

• Highly sophisticated instrumentation required; • Not commercially feasible.

PCT Patent Publication No. WO 2008/106179 discloses a process for the preparation of ramelteon that involves the following reaction steps:

wherein X= O-alkyl or NH2 and chiral reduction of the compound of formula IV in the presence of Ru-BINAP complex under hydrogen atmosphere in an organic solvent.

IV V

The process disclosed in WO 2008/106179 is similar to the process disclosed in United States Patent No. 6,034,239 and the Journal of Medicinal Chemistry, Vol. 45 in that a Ru-BINAP complex is employed.

Resolution of racemic mixtures via reaction with optically active acids and the subsequent crystallization of the resulting salts is preferably employed when the chiral carbon of the racemic compound is an alpha carbon {i.e., one carbon removed) to the functional group forming the acid addition salt. As the distance between the chiral carbon of the racemic compound to the functional group of the racemic compound increases to beta (i.e., two carbon removed) & gamma (i.e., three carbon removed), the resolution of the diastereomeric salt becomes more difficult and not very useful.

Ramelteon has a chiral center at the gamma carbon, which makes the separation of the isomer with an optically active acid quite a daunting task. Similarly, N-[2-(l, 6, 7, 8,- tetrahydro-2H-indeno [5, 4-b]furan-8-yl)]ethylamine (compound T), an intermediate useful in the production of ramelteon has a chiral center at the gamma carbon which would lead a skilled artisan to believe that optical resolution with an optically active acid could prove difficult.

Synthesis

Chilman-Blair, K.; Castañer, J.; Silvestre, J.S.; Bayés, M. (2003). “TAK-375″. Drugs of the Future 28 (10): 950. doi:10.1358/dof.2003.028.10.763214.

………………..

SYNTHESIS

Scheme 1 :

XIV (S)-XII

……………………………………..

SYNTHESIS

Scheme 2

0-30°C

Metal salt Propionyl halide/

Propionc anhydride

Ramelteon (I)

Synthesis of ramelteon

Preparation 1

N-[2-(l,6,7,8-Tetrahydro-2H-indeno[5,4-b]furan-8-yl)-ethyl]-propionamide (2.0 gm) was dissolved in 50.0 ml (n-Hexane:IPA:DEA) (as used herein, “IPA” stands for isopropyl alcohol, and “DEA” stands for diethylamine)

and optically resolved by high performance column chromatography on CHTRAL PACK IA-3 using Mobile phase : n-Hexane:IPA:DEA Flow rate: 1.0ml/min UV:285 nm; at a column temperature of 25°C;sample concentartion: lmg/ml and, eluted with mobile phase. Both the enantiomers were collected separately and after evaporation of solvent under vacuum, enantiomerically pure ramelteon (I) was obtained. Preparation 2- using Supercritical Fluid Chromatography (SFC)

N-[2-(l56,7,8-Tetrahydro-2H-indeno[5,4-b]furan-8-yl)-ethyl]-propionamide (2.0 gm) was dissolved in 50.0 ml (n-Hexane:Ethanol:DEA) and optically resolved by Supercritical Fluid Chromatography (SFC) on CHIRAL PACK AD-H using a mobile phase : C02/(Methanol/ Diethylamine[DEA]) and eluted with mobile phase. Both the enantiomers were collected separately and after evaporation of solvent under vacuum, enantiomerically pure S- ramelteon of Formula (I) and R-ramelteon were obtained with isomeric purity>99%.

………………………………

SYNTHESIS

synthesis of ramelteon that comprises the step of separating N-[2-(l, 6, 7, 8-tetrahydro-2H-indeno [5, 4-b] furan-8- yl)]ethylamine (compound 2) into its isomers using an optically active acid to achieve high enantioselectivity of the desired isomer. This embodiment may further include the step of acylating the substantially pure enantiomer, (S)-N-[2-(l, 6, 7, 8-tetrahydro-2H-indeno [5, 4-b] furan-8-yl)]ethylamine (compound (S)-2) using a suitable acylating agent, such as propionyl chloride) to provide (S)-7V-[2-(l,6,7,8-tetrahydro-2H-indeno[5,4-b]furan-8-yl]ethyl]propionamide (ramelteon or compound 1) substantially free of the (R)-isomer.

One embodiment of the present invention for the preparation of ramelteon is shown below in Scheme 1.

Example 1

Preparation of (S)-N-2-(l, 6, 7, 8-tetrahydro-2H-indeno [5, 4-b] furan-8-yl) ethylamine (Compound (S)-2)

A solution of N-[2-(l, 6, 7, 8-tetrahydro-2H-indeno [5, 4-b] furan-8-yl)ethylamine (45 g; 0.22 mol) in methanol (225 ml) is added to a solution of S-(+)-2-(4-isobutylphenyl)propionic acid (41 g; 0.20 mol) in methanol (205 ml) at 25-300C. The reaction mixture is concentrated to dryness under reduced pressure. The crude salt precipitated is recrystallized in methanol to give a diastereomeric salt of (S)-N-2-(l, 6, 7, 8-tetrahydro-2H-indeno [5, 4-b] furan-8-yl) ethylamine with (S)-(+)-2-(4-isobutylphenyl) propionic acid having a chiral purity of greater than 90% enantioselectivity. The product obtained is recrystallized from methanol to give the pure salt having chiral purity of 99% or greater enantioselectivity.

The purified salt is suspended in water and the pH of the suspension is adjusted to 11-12 using aqueous sodium hydroxide. The reaction mixture is extracted with dichloromethane, washed with water and evaporated to give the pure (S)-N-[2-(l, 6, 7, 8-tetrahydro-2H-indeno [5, 4-b] furan-8-yl)]ethylamine (compound (S)-2), substantially free from its (R) isomer.

Example 2

Preparation of (S)-N-[2-(l, 6, 7, 8-tetrahydro-2H-indeno [5, 4-b] furan-8-yl)ethyl] propionamide (ramelteon)

Triethyl amine (15.15 g, 0.15 mol) and propionyl chloride (13.66 g, 0.15 mol) were added to a solution of S-[2-(l, 6, 7, 8-tetrahydro-2H-indeno [5,4-b]furan-8-yl)]ethylamine (25 g, 0.12 mol) (compound (S)-2) (prepared in Example 1) in dichloromethane and stirred at room temperature for 2 hours. 75 mL water was added to the reaction mixture, and the layers were separated. The dichloromethane layer was concentrated under reduced pressure and purified from a mixture of acetone and hexane to give (S)-N-[2-(l, 6, 7, 8-tetrahydro-2H-indeno [5, 4-b] furan- 8-yl) ethyl] propionamide (compound 1) having a chiral purity of 99% or greater enantioselectivity.

…………

INTERMEDIATES

The intermediate compound of formula Vl, 6,7-dihydro-1 H-indeno[5,4-b]furan-8(2H)-one, can then be subjected to further synthesis steps to yield ramelteon by synthesis route known to or readily devisable by a person skilled in the art, suitably involving the introduction of the side chain having chirality and amide function. The documents mentioned infra are incorporated herein by way of reference. For example, the following synthesis route may be applied:

1 ) NaOH

Vl 2) H2, Ru-BI NAP

3) HCI

4) H2, Pd/C

Experimental Procedures

Example 1 :

Preparation of 4-(2-chloroethyl)-2,3-dihydrobenzofuran (II)

intermediate FTIR spectra of MeCN (140 ml) was recorded as reference. MeCN was cooled to -200C, oxalyl chloride (16.5 ml) was added at once and waited until temperature re-stabilized at – 200C. DMF (16.6 ml) was then added drop-wise (temperature between -18°C and -22°C, 0.5 ml/min). Reaction was stirred until no oxalyl chloride was visible and DMF level was stable by FTIR. Vilsmeier reagent is thereby formed in situ according to the following reaction:

Product I was then added portion wise (temperature between -18°C and -210C, about 30 min). Formation of intermediate was immediately observed by FTIR. Reaction was stirred for one hour. Et3N was then added drop-wise (temperature between -18°C and -22°C, 50 ml/h). At the end of addition, reaction was stirred 15 min at -200C and temperature was slowly raised to 500C (within about 15 min). Disappearance of intermediate and formation of DMF and product Il was monitored by FTIR. When reaction looked completed by FTIR (about 2h at 50°C), the reaction was cooled down to 200C and quenched with water (45 ml). Solution was transferred to a round bottom flask and MeCN was removed under reduced pressure. Solution was then diluted with MTBE (100 ml) and water (50 ml). Phases were separated and aqueous phase was re-extracted twice with MTBE (50 ml). Combined organic phases were washed twice with 10% H3Pθ4/10% NaCI solution and stored at 4°C until next step.

List of FTIR bands used to follow the reaction (using 2nd derivative and solvent subtraction): Oxalyl chloride (reactant): Height to two point baseline, peak from 1800 cm“1 to 1770 cm“1, baseline 1800 cm“1 to 1770 cm“1.

Intermediate: Height to single point baseline, peak from 1722 cm“1 to 1712 cm“1, baseline

1722 cm“1.

Compound Il (product): Area to two point baseline, peak from 993 cm“1 to 981 cm“1, baseline 993 cm“1 to 981 cm“1.

DMF: Height to single point baseline, peak from 1694 cm“1 to 1680 cm“1, baseline 1694 cm“1.

Example 2:

Preparation of 4-vinyl-2,3-dihydrobenzofuran (III)

M FTIR spectra of MTBE was recorded prior to the reaction as reference. To the solution of 4- (2-chloroethyl)-2,3-dihydrobenzofuran (II) in MTBE (150 ml) obtained at the previous step, was added, water (38 ml), Kl (1.37 g), Bu4NOH 40% (19 ml) and NaOH 50% solution (66 ml). Reaction was vigorously stirred and heated at 500C until reaction looked completed by FTIR (4 to 5 h). Warm reaction mixture was then transferred into an extraction funnel to give three phases. Water phase (bottom) was removed and did not contain product. Medium phase (colored black) was diluted with water (120 ml) and was extracted three times with MTBE. Combined organic phases were washed twice with water, once with 0.5M NaHSO3/10% NaCI solution and once with 1 N NaOH/10% NaCI solution. MTBE solution was dried using MgSO4, filtered, concentrated and used immediately for next step.List of FTIR bands used to follow the reaction (using 2nd derivative and solvent subtraction) Compound Il (reactant): Area to zero, peak from 1440 cm“1 to 1437 cm“1 Compound III (product): Area to zero, peak from 1417 cm“1 to 1412 cm“1. Compound III (product): Area to zero, peak from 1565 cm“1 to 1562 cm“1.

Example 3:

Preparation of 1-(2,3-dihydrobenzofuran-4-yl)ethanone (V)

4-vinyl-2,3-dihydrobenzofuran (I I I ) (2.4 g) was dissolved in toluene (2 ml) and were successively added (ITC) (51 mg), PdCI2(30 mg) and H2O2 30% (2 ml). Reaction was vigorously stirred at 55°C until reaction looked completed by FTIR. (for around 24 h). Reaction was cooled down to room temperature, diluted with EtOAc (50 ml) and water (50 ml). Phases were separated and organic phase was washed with 0.5M NaHSO3/10% NaCI solution and twice with 1 M NaHCO3, dried over MgSO4 and concentrated. Purification by flash chromatography gave 1-(2,3-dihydrobenzofuran-4-yl)ethanone (V). 1H NMR δ (CDCI3) 7.35 (dd, 1 H, J = 0.8 Hz, J = 7.8 Hz), 7.19 (t, 1 H, J = 7.9 Hz), 6.95 (d, 1 H, J = 8.0 Hz), 4.57 (t, 2H, J = 8.8 Hz), 3.52 (t, 2H, J = 8.8 Hz), 2.57 (s, 3H). 13C NMR δ (CDCI3) 198.8, 161.0, 133.8, 128.2, 127.9, 121.4, 1 13.4, 71.6, 31.0, 27.6.

List of FTIR bands used to follow the reaction (using 2nd derivative and solvent subtraction) Compound III (reactant): Area to single point baseline, peak from 925 cm“1 to 915 cm“1, baseline 915 cm“1.

Compound V (product): Area to zero, peak from 1730 cm“1 to 1724 cm“1.

Example 4:

Preparation of 6,7-dihydro-1 H-indeno[5,4-b]furan-8(2H)-one (Vl)

V Vl1 -(2,3-dihydrobenzofuran-4-yl)ethanone (V) (1 g, 6.2 mmol) was dissolved in dioxane (9 ml). TADCA (dicyclohexylammonium 2,2,2-trifluoroacetate) (1 .82 g, 1 eq) and paraformaldehyde (0.61 1 g, 1.1 eq) were added. The reaction was heated at 1000C for 2 h. A second portion of TADCA (0.91 g, 0.5 eq) and paraformaldehyde (0.333 g, 0.6 eq) were added and the reaction was heated at 1000C for 2 h. Reaction was partitioned between water (20 ml) and pentane (30 ml). Aqueous phase was re-extracted 4 times with pentane (10 ml). Combined pentane phases were washed with water and brine, dried over MgSO4. Solution was diluted to 100 ml with pentane. This solution was added dropwise to a pre-heated solution of sulfuric acid at 67°C (10 ml) under nitrogen stream. At the end of addition, the reaction was stirred for 30 min. Reaction was cooled down to room temperature and poured on iced water (50 ml). Solution was extracted 5 times with MTBE. Combined organic phases were washed with water, NaHCO3 1 M and brine, dried over MgSO4 and concentrated. Purification by flash chromatography furnished pure 6,7-dihydro-1 H-indeno[5,4-b]furan-8(2H)-one (Vl). 1H NMR δ (CDCI3) 7.21 (dd, 1 H, J = 0.9 Hz, J = 9.0 Hz), 7.02 (d, 1 H, J = 8.2 Hz), 4.66 (t, 2H, J = 8.9 Hz), 3.48 (t, 2H, J = 8.9 Hz), 3.08 (dd, 2H, J = 4.9 Hz, J = 6.0 Hz), 2.69 (m, 2H). 13C NMR δ (CDCI3) 207.5, 160.2, 147.1 , 133.6, 125.6, 123.9, 1 15.6, 72.3, 37.1 , 28.4, 25.4.

…………………………………

SYNTHESIS

Improve the synthesis and flow properties of an insomnia drug.

Ramelteon (1), marketed as Rozerem by Takeda Pharmaceuticals, is used to treat insomnia. V. K. Kansal and co-inventors describe several processes that are used to prepare it, all of which require many steps. The inventors offer no comments about the relative merits of the processes, but they state that a new industrial-scale process is needed. Their main claims are to intermediate acid 2 as a racemic mixture and individual enantiomers; one enantiomer is converted to 1 by the route shown in Figure 1.

The inventors use diastereomeric crystallization to resolve the racemic mixture by forming its (S)-1-phenylethylamine salt. The salt of the (R)-isomer of 2 is recovered first; then the salt of (S)-2 is isolated from the solution and acidified to give the free acid, which is purified by using (R)-1-phenylethylamine. Both enantiomers are isolated with >99.0% purity and >99.0% ee.

The (S)-acid is converted to acid chloride 3 and then to amide 4 by reactions with SOCl2and NH3 gas, respectively. The chloride is not isolated; the amide is recovered in 85–90% yield with 95–98% purity. When aq NH4OH is used instead of NH3 gas, the purity of 4 is slightly lower (93–96%). An alternative method for preparing 4 is to treat 2 with Et3N and ClCO2Et, followed by NH3. This method produces 4 in yields of 80–95% and 97–99% purity.

Amide 4 is reduced to amine 5 with NaBH4 and BF3·Et2O. The amine is purified by forming its chloride or oxalate salt in yields as high as 85% and 96–98% purity. The salts are used to prepare 1 by treating them with EtCOCl in the presence of base: NaOH for the chloride salt and Na2CO3 for the oxalate. In both cases, the yield of 1 is >92%, and the purity is as high as 99.9% after recrystallization from EtOH.

The inventors also recrystallized 1 from toluene to produce what they describe as a “nonelectrostatic” crystalline form, designated as form A. They describe the measurement of the electrostatic charge of the crystals in one of the patent’s examples. The measurements show that the average charge density of form A is ≈15 times lower than crystals obtained from EtOAc. Low electrostatic charge improves the flow characteristics of the solid, which is important in preparing drug formulations.

The inventors report the details of preparing rac-2 by a multistep procedure shown in Figure 2.

In most of the reaction steps, the product is isolated in crude form; the inventors do not indicate whether the product is purified before it is used in the next stage. The synthesis of rac-2 begins with the conversion of benzofuran (6) to aldehyde7 by treatment with POCl3 followed by hydrolysis. The crude product is isolated as a liquid in 85–90% yield and 90–92% purity.

In the next step, 7 is condensed with malonic acid (8) in the presence of piperidine and HOAc; acid 9 is isolated in 92–95% yield and 95% purity. Catalytic hydrogenation of 9produces 10 in 95% yield and 94–96% purity. The hydrogenation also can be carried out in the presence of NaOH and HCO2NH4; the yield and purity of 10 are the same, but the reaction takes 6 h instead of 2 h. [The patent does not state why NaOH and HCO2NH4 would be used.—Ed.] Acid 10 is brominated to produce acid 11, isolated in 50–60% yield and 92–95% purity.

The next stage begins with treating 11 with SOCl2 to activate the carboxyl group by forming acid chloride 12. The chloride is not isolated but cyclized under Friedel–Crafts conditions to give tricyclic compound 13, isolated in yields of 85–92% and 90-95% purity. This reaction also produces two impurities, 14 and 15, but the amounts are not reported. Removing the impurities gives 13 in good yield, but the inventors do not describe how this is done. They do report that the impurities can be isolated, and 1H and 13C NMR data are provided for both.

In the next step, the bromine atoms in 13 are replaced by hydrogen to give 16 in 85–90% yield and 96–97%purity. This reaction produces two impurities, 17 and 18; again, the amounts are not reported, but 1H and 13C NMR data are. After MeOH reflux in the presence active carbon, 16 is isolated in 80–85% yield with 99.3–99.8% purity. It is then converted to ester 20 by treating it with a solution of phosphonate 19 that contains suspended NaH. Crude product 20 is isolated in 80–85% yield and 92–95% purity as a mixture of (E)- and (Z)-isomers. The isomer mixture is hydrogenated, and base hydrolysis gives rac-2 in 90–95% isolated yield and 95–98% purity.

The inventors claim that the overall process is suitable for producing ramelteon on an industrial scale in a crystalline form that has improved flow characteristics. (Teva Pharmaceutical Industries [Petah Tiqva, Israel]. US Patent 8,084,630, Dec. 27, 2011;

RAMELTEON

RAMELTEON

…………………….

SYNTHESIS

CHINESE CHEMICAL LETTERS 22, 2011, 264 SEE SYN OF KEY INTERMEDIATE

1:RAMELTEON

[a]D20 10.0 (c, 0.20, EtOH); mp 76–77 8C;

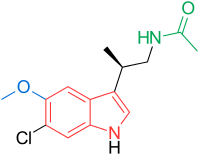

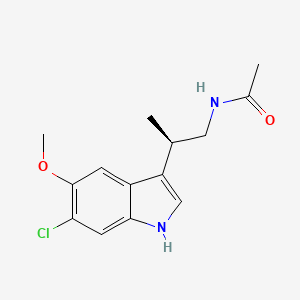

1H NMR (500 MHz, CDCl3): d1.15 (t, 3H, J = 7.5 Hz), 1.60 (m, 1H), 1.70 (m, 1H), 2.02 (m, 1H), 2.19 (q, 2H, J = 7.5 Hz), 2.32 (m, 1H), 2.76 (m, 1H), 2.85 (m, 1H), 3.11 (m,1H), 3.41 (m, 2H), 3.79 (s, 3H), 5.48 (s, 1H), 6.71 (dd, 1H, J = 2.0 Hz, 8.5 Hz), 6.75 (s, 1H), 7.11 (d, 1H, J = 8.0 Hz).

13C NMR (100 MHz,DMSO–d6): d173.7, 158.7, 148.1, 135.8, 124.9, 112.3, 109.2, 55.5, 42.7, 37.9, 34.8, 32.5, 30.6, 29.8, 9.9. EI-MS: 247 ([M]+); HR-MS 247.1572([M]+

, C15H21NO2; Calcd. 247.1571). The enantiomeric excess of (S)-1 was determined by HPLC as >99.9% [column, CHIRALPAK AS-H

(4.6 mm 250 mm), room temperature; eluent, hexane-2-propanol-trifluoroacetic acid (90:10:0.1); flow rate, 1.0 mL/min; detect, 290 nm; tRof (S)-1, 30.7 min; tR of (R)-1 (enantiomer of (S)-1), 37.1 min].

, C15H21NO2; Calcd. 247.1571). The enantiomeric excess of (S)-1 was determined by HPLC as >99.9% [column, CHIRALPAK AS-H

(4.6 mm 250 mm), room temperature; eluent, hexane-2-propanol-trifluoroacetic acid (90:10:0.1); flow rate, 1.0 mL/min; detect, 290 nm; tRof (S)-1, 30.7 min; tR of (R)-1 (enantiomer of (S)-1), 37.1 min].

…………………….

NMR

- dmd.aspetjournals.org/content/suppl/…/Supplemental_Information.pptx

May 17, 2010 - Ramelteon NMR Assignments. COSY: Black Arrows. HMBC: Red Arrows. Figure S-1b. 1H NMR Spectrum of Ramelteon. Figure S-1c.

References

- Owen RT (April 2006). “Ramelteon: profile of a new sleep-promoting medication”. Drugs Today 42 (4): 255–63. doi:10.1358/dot.2006.42.4.970842. PMID 16703122.

- Miyamoto M, Nishikawa H, Doken Y, Hirai K, Uchikawa O, Ohkawa S (November 2004). “The sleep-promoting action of ramelteon (TAK-375) in freely moving cats”. Sleep 27 (7): 1319–25.PMID 15586784.

- Zammit G, Erman M, Wang-Weigand S, Sainati S, Zhang J, Roth T (August 2007). “Evaluation of the Efficacy and Safety of Ramelteon in Subjects with Chronic Insomnia”. J Clin Sleep Med 3 (5): 495–504. PMC 1978328. PMID 17803013.

- Daniel F. Kipke, MD |title=Evidence That New Hypnotics Cause Cancer |journal=University of California |date=March 2008 |url=http://escholarship.org/uc/item/12r2f32g#page-2

- http://db.wdc-jp.com/cgi-bin/psj/data/cpb/pdf/201108/c08_1062.pdf

- http://sat.ecnu.edu.cn/Uploadnews/20120213113859628.pdf

- https://docs.google.com/viewer?url=http%3A%2F%2Fdmd.aspetjournals.org%2Fcontent%2Fsuppl%2F2010%2F05%2F17%2Fdmd.110.034009.DC1%2FSupplemental_Information.pptx

Full-Text PDF – MDPI.com

- Rozerem Official Website

- Prescribing Information Data Sheet

- RxList.com

- Clinical Pharmacokinetic Monitoring of Midazolam in Critically Ill Patients in relation to midazolam as a drug-drug interaction to Rozerem

| WO2008106179A1 | Feb 26, 2008 | Sep 4, 2008 | Teva Pharma | Intermediates and processes for the synthesis of ramelteon |

| WO2008151170A2 | Jun 2, 2008 | Dec 11, 2008 | Teva Pharma | Process for the synthesis of ramelteon and its intermediates |

| EP0885210B1 | Mar 5, 1997 | Jun 12, 2002 | Takeda Chemical Industries, Ltd. | Tricylic compounds having binding affinity for melatonin receptors, their production and use |

| EP1792899A1 | Sep 12, 2005 | Jun 6, 2007 | Takeda Pharmaceutical Company Limited | Process for production of optically active amine derivatives |

| US6034239 * | Mar 6, 1997 | Mar 7, 2000 | Takeda Chemical Industries, Ltd. | Tricyclic compounds, their production and use |

| US20010039286 * | Feb 13, 2001 | Nov 8, 2001 | Kevin Dinnell | 2-aryl indole derivatives and their use as therapeutic agents |

| WO2006030739A1 | Sep 12, 2005 | Mar 23, 2006 | Takeda Pharmaceutical | Process for production of optically active amine derivatives |

| WO2008062468A2 | Oct 15, 2007 | May 29, 2008 | Cadila Healthcare Ltd | Process for the preparation of optically pure indeno [5,4-b] furan derivatives |

| WO2008106179A1 | Feb 26, 2008 | Sep 4, 2008 | Teva Pharma | Intermediates and processes for the synthesis of ramelteon |

| WO2009106966A1 | Feb 27, 2009 | Sep 3, 2009 | Medichem, S.A. | Process for preparing ramelteon. |

| WO2010055481A1 | Nov 12, 2009 | May 20, 2010 | Watson Pharma Private Limited | Process for the preparation of ramelteon |

| WO2010092107A1 * | Feb 11, 2010 | Aug 19, 2010 | Lek Pharmaceuticals D.D. | Synthesis of (s)-n-[2-(1,6,7,8-tetrahydro-2h-indeno-[5,4-b]furan-8-yl)ethyl]propionamide |

| WO2010103553A1 * | Mar 10, 2009 | Sep 16, 2010 | Industriale Chimica S.R.L. | Process for the preparation of ramelteon |

| EP0885210A1 | Mar 5, 1997 | Dec 23, 1998 | Takeda Chemical Industries, Ltd. | Tricyclic compounds, their production and use |

| US6034239 | Mar 6, 1997 | Mar 7, 2000 | Takeda Chemical Industries, Ltd. | Tricyclic compounds, their production and use |

| US20100152468 | Oct 16, 2009 | Jun 17, 2010 | Teva Pharmaceutical Industries Ltd. | Process for the synthesis of ramelteon and its intermediates |

| WO2008062468A2 * | Oct 15, 2007 | May 29, 2008 | Cadila Healthcare Ltd | Process for the preparation of optically pure indeno [5,4-b] furan derivatives |

| US5321154 * | Jul 31, 1992 | Jun 14, 1994 | Nagase & Company, Ltd. | Optical resolution of (.+-.)-2-(4-isobutylphenyl)-propionic acid |

| US6218429 * | May 10, 1999 | Apr 17, 2001 | Takeda Chemical Industries, Ltd. | Tricyclic compounds, their production and use |

| US6348485 * | Jun 8, 1999 | Feb 19, 2002 | Takeda Chemical Industries, Ltd. | Method for treating or preventing sleep disorders |

| US20080214559 * | Jan 7, 2008 | Sep 4, 2008 | Solvay Pharmaceuticals B.V. | Compounds with a combination of cannabinoid cb1 antagonism and serotonin reuptake inhibition |

| US20080242877 * | Feb 26, 2008 | Oct 2, 2008 | Vinod Kumar Kansal | Intermediates and processes for the synthesis of Ramelteon |

| WO2012035303A2 | Sep 16, 2011 | Mar 22, 2012 | Cipla Limited Et Al | A novel process for synthesis of ramelteon, and key intermediates for the synthesis of ramelteon |

2.........

TASIMELTEON

TASIMELTION, an orphan drug for non24

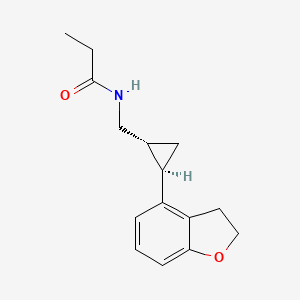

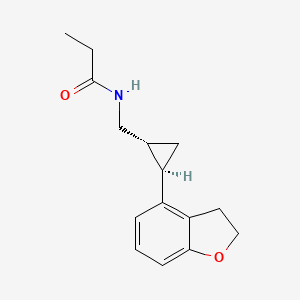

N-([(1R,2R)-2-(2,3-Dihydro-1-benzofuran-4-yl)cyclopropyl]methyl)propanamide

(1R-trans)-N-[[2-(2,3-dihydro-4-benzofuranyl)cyclopropyl]methyl]pro- pananamide VEC162

(-)-(trans)-N-[[2-(2,3-Dihydrobenzofuran-4-yl)cycloprop-1-yl]methyl]propanamide

N-(((1R,2R)-2-(2,3-Dihydro-1-benzofuran-4-yl)cyclopropyl)methyl)propanamide

Bristol-Myers Squibb Company

PRODUCT PATENT

U.S. Pat. No. 5,856,529

| CAS NUMBER | 609799-22-6 |

|---|

| FORMULA | C15H19NO2 |

|---|---|

| MOL. MASS | 245.3 g/mol |

VEC-162, BMS-214778, 609799-22-6, Hetlioz, UNII-SHS4PU80D9,

January 31, 2014 — The U.S. Food and Drug Administration today approved Hetlioz (tasimelteon), a melatonin receptor agonist, to treat non-24- hour sleep-wake disorder (“non-24”) in totally blind individuals. Non-24 is a chronic circadian rhythm (body clock) disorder in the blind that causes problems with the timing of sleep. This is the first FDA approval of a treatment for the disorder.

Non-24 occurs in persons who are completely blind. Light does not enter their eyes and they cannot synchronize their body clock to the 24-hour light-dark cycle.

Tasimelteon

TASIMELTION , BMS-214,778) is a drug which is under development for the treatment of insomnia and other sleep disorders.[1] It is a selective agonistfor the melatonin receptors MT1 and MT2 in the suprachiasmatic nucleus of the brain, similar to older drugs such as ramelteon.[2] It has been through Phase III trials successfully and was shown to improve both onset and maintenance of sleep, with few side effects.[3]

A year-long (2011-2012) study at Harvard is testing the use of tasimelteon in blind subjects with non-24-hour sleep–wake disorder.[4] In May 2013Vanda Pharmaceuticals submitted a New Drug Application to the Food and Drug Administration for Tasimelteon for the treatment of non-24-hour sleep–wake disorder in totally blind people.[5]

SEQUENCE

Discovered by Bristol-Myers Squibb (BMS) and co-developed with Vanda Pharmaceuticals, tasimelteon is a hypnotic family benzofuran. In Phase III development, it has an orphan drug status.

JAN2014.. APPROVED FDA

In mid-November 2013 the FDA announced their recommendation for the approval of Tasimelteon for the treatment of non-24-disorder.Tasimelteon effectively resets the circadian rhythm, helping to restore normal sleep patterns.http://www.fda.gov/downloads/AdvisoryCommittees/CommitteesMeetingMaterials/Drugs/PeripheralandCentralNervousSystemDrugsAdvisoryCommittee/UCM374388.pdf

January 2010: FDA granted orphan drug tasimelteon to disturbed sleep / wake in blind without light perception.

February 2008: Vanda has completed enrollment in its Phase III trial in chronic primary insomnia.

June 2007: Results of a Phase III trial for transient insomnia tasimelteon presented by Vanda at the 21st annual meeting of the Associated Professional Sleep Societies. These results demonstrated improvements in objective and subjective measures of sleep and its maintenance.

2004 Vanda gets a license tasimelteon (or BMS-214778 and VEC-162) from Bristol-Myers Squibb.

About Tasimelteon: Tasimelteon is a circadian regulator in development for the treatment of Non-24. Tasimelteon is a dual melatonin receptor agonist (DMRA) with selective agonist activityat the MT1 and MT2 receptors.Tasimelteon’s ability to reset the master body clock in the suprachiasmatic nucleus (SCN) results in the entrainment of the body’s melatonin and cortisol rhythms with the 24-hour day-night cycle. The patent claiming tasimelteon as a new chemical entity extends through December 2022, assuming a 5-year extension to be granted under the Hatch-Waxman Act. Tasimelteon has been granted orphan drug designation for the treatment of Non-24 from both the U.S. and the European Union.

Previously, BMS-214778, identified as an agonist of melatonin receptors, has been the subject of pre-clinical studies for the treatment of sleep disorders resulting from a disturbance of circadian rhythms.The first Pharmacokinetic studies were performed in rats and monkeys.

The master body clock controls the timing of many aspects of physiology, behavior and metabolism that show daily rhythms, including the sleep-wake cycles, body temperature, alertness and performance, metabolic rhythms and certain hormones which exhibit circadian variation. Outputs from the suprachiasmatic nucleus (SCN) control many endocrine rhythms including those of melatonin secretion by the pineal gland as well as the control of cortisol secretion via effects on the hypothalamus, the pituitary and the adrenal glands.

This master body clock, located in the SCN, spontaneously generates rhythms of approximately 24.5 hours. These non-24-hour rhythms are synchronized each day to the 24-hour day-night cycle by light, the primary environmental time cue which is detected by specialized cells in the retina and transmitted to the SCN via the retino-hypothalamic tract. Inability to detect this light signal, as occurs in most totally blind individuals, leads to the inability of the master body clock to be reset daily and maintain entrainment to a 24-hour day.

Non-24-Hour Disorder

Non-24, also referred to as Non-24-Hour Sleep-Wake Disorder (N24HSWD) or Non-24-Hour Disorder, is an orphan indication affecting approximately 65,000 to 95,000 people in the U.S. and 140,000 in Europe. Non-24 occurs when individuals, primarily blind with no light perception, are unable to synchronize their endogenous circadian pacemaker to the 24-hour light/dark cycle. Without light as a synchronizer, and because the period of the internal clock is typically a little longer than 24 hours, individuals with Non-24 experience their circadian drive to initiate sleep drifting later and later each day. Individuals with Non-24 have abnormal night sleep patterns, accompanied by difficulty staying awake during the day. Non-24 leads to significant impairment, with chronic effects impacting the social and occupational functioning of these individuals.

In addition to problems sleeping at the desired time, individuals with Non-24 experience excessive daytime sleepiness that often results in daytime napping. TASIMELTION

TASIMELTION

TASIMELTION

TASIMELTION

The severity of nighttime sleep complaints and/or daytime sleepiness complaints varies depending on where in the cycle the individual’s body clock is with respect to their social, work, or sleep schedule. The “free running” of the clock results in approximately a 1-4 month repeating cycle, the circadian cycle, where the circadian drive to initiate sleep continually shifts a little each day (about 15 minutes on average) until the cycle repeats itself. Initially, when the circadian cycle becomes desynchronous with the 24 h day-night cycle, individuals with Non-24 have difficulty initiating sleep. As time progresses, the internal circadian rhythms of these individuals becomes 180 degrees out of synchrony with the 24 h day-night cycle, which gradually makes sleeping at night virtually impossible, and leads to extreme sleepiness during daytime hours.

Eventually, the individual’s sleep-wake cycle becomes aligned with the night, and “free-running” individuals are able to sleep well during a conventional or socially acceptable time. However, the alignment between the internal circadian rhythm and the 24-hour day-night cycle is only temporary. In addition to cyclical nighttime sleep and daytime sleepiness problems, this condition can cause deleterious daily shifts in body temperature and hormone secretion, may cause metabolic disruption and is sometimes associated with depressive symptoms and mood disorders.

It is estimated that 50-75% of totally blind people in the United States (approximately 65,000 to 95,000) have Non-24. This condition can also affect sighted people. However, cases are rarely reported in this population, and the true rate of Non-24 in the general population is not known.

The ultimate treatment goal for individuals with Non-24 is to entrain or synchronize their circadian rhythms into an appropriate phase relationship with the 24-hour day so that they will have increased sleepiness during the night and increased wakefulness during the daytime.

INTRODUCTION

Tasimelteon has the chemical name: trans-N-[[2-(2,3-dihydrobenzofuran-4-yl)cycloprop-1yl]methyl]propanamide, has the structure of Formula I:

and is disclosed in U.S. Pat. No. 5,856,529 and in US 20090105333, both of which are incorporated herein by reference as though fully set forth.

Tasimelteon is a white to off-white powder with a melting point of about 78° C. (DSC) and is very soluble or freely soluble in 95% ethanol, methanol, acetonitrile, ethyl acetate, isopropanol, polyethylene glycols (PEG-300 and PEG-400), and only slightly soluble in water. The native pH of a saturated solution of tasimelteon in water is 8.5 and its aqueous solubility is practically unaffected by pH. Tasimelteon has 2-4 times greater affinity for MT2R relative to MT1R. It’s affinity (Ki) for MT1R is 0.3 to 0.4 and for MT2R, 0.1 to 0.2. Tasimelteon is useful in the practice of this invention because it is a melatonin agonist that has been demonstrated, among other activities, to entrain patients suffering from Non-24.

………………………..

SYNTHESIS

(1R-trans)-N-[[2 – (2,3-dihydro-4 benzofuranyl) cyclopropyl] methyl] propanamide PATENT: BRISTOL-MYERS SQUIBB PRIORITY DATE: 1996 HYPNOTIC

PREPARATION OF XV

XXIV D-camphorsulfonic acid IS REACTED WITH THIONYL CHLORIDE TO GIVE

…………XXV (1S, 4R) -7,7-dimethyl-2-oxo-bicyclo [2.2.1] heptane-1-methanesulfonyl chloride

TREATED WITH

XXVI ammonium hydroxide

TO GIVE

XXVII (1S, 4R) -7,7-dimethyl-2-oxo-bicyclo [2.2.1] heptane-1-methanesulfonamide

TREATED WITH AMBERLYST15

….XXVIII (3aS, 6R) -4,5,6,7-tetrahydro-8 ,8-dimethyl-3H-3a ,6-methano-2 ,1-benzisothiazole-2 ,2-dioxide

TREATED WITH LAH, ie double bond is reduced to get

…..XV (3aS, 6R, 7aR)-hexahydro-8 ,8-dimethyl-3H-3a ,6-methano-2 ,1-benzisothiazole-2 ,2-dioxide

Intermediate

I 3-hydroxybenzoic acid methyl ester

II 3-bromo-1-propene

III 3 – (2-propenyloxy) benzoic acid methyl ester

IV 3-hydroxy-2-(2-propenyl) benzoic acid methyl ester

V 2,3-dihydro-4-hydroxy-2-benzofurancarboxylic acid methyl ester

VI benzofuran-4-carboxylic acid methyl ester

VII benzofuran-4-carboxylic acid

VIII 2,3-dihydro-4-benzofurancarboxylic acid

IX 2,3-dihydro-4-benzofuranmethanol

X 2,3-dihydro-4-benzofurancarboxaldehyde

XI Propanedioic acid

XII (E) -3 – (2,3-dihydro-4-benzofuranyl) propenoic acid

XIII thionyl chloride

XIV (E) -3 – (2,3-dihydro-4-benzofuranyl) propenoyl chloride

XV (3aS, 6R, 7aR)-hexahydro-8 ,8-dimethyl-3H-3a ,6-methano-2 ,1-benzisothiazole-2 ,2-dioxide

XVI (3aS,6R,7aR)-1-[(E)-3-(2,3-dihydro-4-benzofuranyl)-1-oxo-2-propenyl]hexahydro-8,8-dimethyl-3H-3a,6-methano-2,1-benzisothiazole-2,2-dioxide

XVII (3aS,6R,7aR)-1-[[(1R,2R)-2-(2,3-dihydro-4-benzofuranyl)cyclopropyl]carbonyl]hexahydro-8,8-dimethyl-3H-3a,6-methano-2,1-benzisothiazole-2,2-dioxide

XVIII [R-(R *, R *)] -2 – (2,3-dihydro-4-benzofuranyl) cyclopropanemethanol

XIX [R-(R *, R *)] -2 – (2,3-dihydro-4-benzofuranyl) cyclopropanecarboxaldehyde

XX hydroxylamine hydrochloride

XXI [R-(R *, R *)] -2 – (2,3-dihydro-4-benzofuranyl) cyclopropanecarbaldehyde oxime

XXII [R-(R *, R *)] -2 – (2,3-dihydro-4-benzofuranyl) cyclopropanemethanamine

XXIII propanoyl chloride

XXIV D-camphorsulfonic acid

XXV (1S, 4R) -7,7-dimethyl-2-oxo-bicyclo [2.2.1] heptane-1-methanesulfonyl chloride

XXVI ammonium hydroxide

XXVII (1S, 4R) -7,7-dimethyl-2-oxo-bicyclo [2.2.1] heptane-1-methanesulfonamide

XXVIII (3aS, 6R) -4,5,6,7-tetrahydro-8 ,8-dimethyl-3H-3a ,6-methano-2 ,1-benzisothiazole-2 ,2-dioxide

Bibliography

- Patents: Benzofuran and dihydrobenzofuran melatonergic agents: US5856529 (1999)

Priority: US19960032689P, 10 Dec. 1996 (Bristol-Myers Squibb Company, U.S.)

- Preparation III (quinazolines): US2004044015 (2004) Priority: EP20000402845, 13 Oct. 2000

- Preparation of VII (aminoalkylindols): Structure-Activity Relationships of Novel Cannabinoid Mimetics Eissenstat et al, J.. Med. Chem. 1995, 38, 3094-3105

- Preparation XXVIII: Towson et al. Organic Syntheses, Coll. Vol. 8, p.104 (1993) Vol. 69, p.158 (1990)

- Preparation XV: Weismiller et al. Organic Syntheses, Coll. Vol. 8, p.110 (1993) Vol. 69, p.154 (1990).

- G. Birznieks et al. Melatonin agonist VEC-162 Improves sleep onset and maintenance in a model of transient insomnia. Sleep 2007, 30, 0773 Abstract.

-. Rajaratnam SM et al, The melatonin agonist VEC-162 Phase time immediately advances the human circadian system, Sleep 2006, 29, 0159 Abstract.

-. AK Singh et al, Evolution of a manufacturing route for a highly potent drug candidate, 229th ACS Natl Meet, March 13-17, 2005, San Diego, Abstract MEDI 576.

- Vachharajani NN et al, Preclinical pharmacokinetics and metabolism of BMS-214778, a novel melatonin receptor agonist, J Pharm Sci. 2003 Apr; 92 (4) :760-72.

. – JW Scott et al, Catalytic Asymmetric Synthesis of a melotonin antagonist; synthesis and process optimization. 223rd ACS Natl Meet, April 7-11, Orlando, 2002, Abstract ORGN 186.

…………………….

SYNTHESIS CONSTRUCTION AS IN PATENT

GENERAL SCHEMES

Reaction Scheme 1

The syntheses of the 4-aryl-propenoic acid derivatives, 2 and 3, are shown in Reaction Scheme 1. The starting aldehydes, 1 , can be prepared by methods well known to those skilled in the art. Condensation of malonic acid with the aldehydes, 1, in solvents such as pyridine with catalysts such as piperidine or pyrrolidine, gives the 4-aryl- propenoic acid, 2. Subsequent conversion of the acid to the acid chloride using reagents such as thionyl chloride, phosphoryl chloride, or the like, followed by reaction with N,0-dimethyl hydroxylamine gives the amide intermediate 3 in good yields. Alternatively, aldehyde 1 can be converted directly to amide 3 using reagents such as diethyl (N-methoxy- N-methyl-carbamoylmethyl)phosphonate with a strong base such as sodium hydride.

Reaction Scheme 2

The conversion of the amide intermediate 3 to the racemic, trans- cyclopropane carboxaldehyde intermediate, 4, is shown in Reaction Scheme 2. Intermediate 3 was allowed to react with cyclopropanating reagents such as trimethylsulfoxonium iodide and sodium hydride in solvents such as DMF, THF, or the like. Subsequent reduction using reagents such as LAH in solvents such as THF, ethyl ether, or the like, gives the racemic, trans-cyclopropane carboxaldehyde intermediates, 4.

Reaction Scheme 3

Racemic cyclopropane intermediate 5 (R = halogen) can be prepared from intermediate 2 as shown in Reaction Scheme 3. Intermediate 2 was converted to the corresponding allylic alcohol by treatment with reducing agents such as sodium borohydride plus iodine in solvents such as THF. Subsequent acylation using reagents such as acetic anhydride in pyridine or acetyl chloride gave the allylic acetate which was allowed to react with cyclopropanating reagents such as sodium chloro-difluoroacetate in diglyme to provide the racemic, trans- cyclopropane acetate intermediates, 5. Reaction Scheme 4

The conversion of the acid 2 to the chiral cyclopropane carboxaldehyde intermediate, (-)-(trans)-4, is shown in Reaction Scheme 4. Intermediate 2 is condensed with (-)-2,10-camphorsultam under standard conditions, and then cyclopropanated in the presence of catalysts such as palladium acetate using diazomethane generated from reagents such as 1-methyl-3-nitro-1-nitrosoguanidine. Subsequent reduction using reagents such as LAH in solvents such as THF, followed by oxidation of the alcohol intermediates using reagents such as DMSO/oxalyl chloride, or PCC, gives the cyclopropane carboxaldehyde intermediate, (-)-(trans)-4, in good yields. The enantiomer, (+)-(trans)-4, can also be obtained employing a similar procedure using (+)-2,10- camphorsultam in place of (-)-2,10-camphorsultam.

When it is desired to prepare compounds of Formula I wherein m = 2, the alcohol intermediate may be activated in the conventional manner such as with mesyl chloride and treated with sodium cyanide followed by reduction of the nitrile group with a reducing agent such as LAH to produce the amine intermediate 6.

Reaction Scheme 5

Reaction Scheme 5 shows the conversion of intermediates 4 and 5 to the amine intermediate, 7, and the subsequent conversion of 6. or 7 to compounds of Formula I. The carboxaldehyde intermediate, 4, is condensed with hydroxylamine and then reduced with reagents such as LAH to give the amine intermediate, 7. The acetate intermediate 5 is hydrolyzed with potassium hydroxide to the alcohol, converted to the mesylate with methane sulfonyl chloride and triethyl amine in CH2CI2and then converted to the azide by treatment with sodium azide in solvents such as DMF. Subsequent reduction of the azide group with a reducing agent such as LAH produced the amine intermediate 7. Further reaction of 6 or 7 with acylating reagents gives compounds of Formula I. Suitable acylating agents include carboxylic acid halides, anhydrides, acyl imidazoles, alkyl isocyanates, alkyl isothiocyanates, and carboxylic acids in the presence of condensing agents, such as carbonyl imidazole, carbodiimides, and the like. Reaction Scheme 6

Reaction Scheme 6 shows the alkylation of secondary amides of Formula I (R2 = H) to give tertiary amides of Formula I (R2 = alkyl). The secondary amide is reacted with a base such as sodium hydride, potassium tert-butoxide, or the like, and then reacted with an alkylating reagent such as alkyl halides, alkyl sulfonate esters, or the like to produce tertiary amides of Formula I.

Reaction Scheme 7

Reaction Scheme 7 shows the halogenation of compounds of Formula I. The carboxamides, i (Q1 = Q2 = H), are reacted with excess amounts of halogenating agents such as iodine, N-bromosuccinimide, or the like to give the dihalo-compounds of Formula I (Q1 = Q2 = halogen). Alternatively, a stoichiometric amount of these halogenating agents can be used to give the monohalo-compounds of Formula I (Q1 = H, Q2 = halogen; or Q1 = halogen, Q2 = H). In both cases, additives such as lead IV tetraacetate can be used to facilitate the reaction. Biological Activity of the Compounds

The compounds of the invention are melatonergic agents. They have been found to bind human melatonergic receptors expressed in a stable cell line with good affinity. Further, the compounds are agonists as determined by their ability, like melatonin, to block the forskolin- stimulated accumulation of cAMP in certain cells. Due to these properties, the compounds and compositions of the invention should be useful as sedatives, chronobiotic agents, anxiolytics, antipsychotics, analgesics, and the like. Specifically, these agents should find use in the treatment of stress, sleep disorders, seasonal depression, appetite regulation, shifts in circadian cycles, melancholia, benign prostatic hyperplasia and related conditions

EXPERIMENTAL PROCEDURES

SEE ORIGINAL PATENT FOR CORECTIONS

Preparation 1

Benzofuran-4-carboxaldehyde

Step 1 : N-Methoxy-N-methyl-benzofuran-4-carboxamide

A mixture of benzofuran-4-carboxylic acid [Eissenstat, et al.. J. Medicinal Chemistry, 38 (16) 3094-3105 (1995)] (2.8 g, 17.4 mmol) and thionyl chloride (25 mL) was heated to reflux for 2 h and then concentrated in vacuo. The solid residue was dissolved in ethyl acetate (50 mL) and a solution of N,O-dimethylhydroxylamine hydrochloride (2.8 g) in saturated NaHC03(60 mL) was added with stirring. After stirring for 1.5 h, the ethyl acetate layer was separated. The aqueous layer was extracted with ethyl acetate. The ethyl acetate extracts were combined, washed with saturated NaHCO3 and concentrated in vacuo to give an oil (3.2 g, 95.4%).

Step 2: Benzofuran-4-carboxaldehyde

A solution of N-methoxy-N-methyl-benzofuran-4-carboxamide (3.2 g, 16.6 mmol) in THF (100 mL) was cooled to -45°C and then LAH (0.7 g, 18.7 mmol) was added. The mixture was stirred for 15 min, allowed to warm to -5°C, and then recooled to -45°C. Saturated KHS04 (25 mL) was added with vigorous stirring, and the mixture was allowed to warm to room temperature. The precipitate was filtered and washed with acetone. The filtrate was concentrated in vacuo to give an oil (2.3 g, 94%). Preparation 2

2,3-Dihydrobenzofuran-4-carboxaldehyde

Step 1 : 2,3-Dihydrobenzofuran-4-carboxylic acid

Benzofuran-4-carboxylic acid (10.0 g, 61 .7 mmol) was hydrogenated (60 psi) in acetic acid (100 mL) over 10% Pd/C (2 g) for 12 hr. The mixture was filtered and the filtrate was diluted with water (500 mL) to give 2,3- dihydrobenzofuran-4-carboxylic acid as a white powder (8.4 g, 83%). A sample was recrystallized from isopropanol to give fine white needles (mp: 185.5-187.5°C).

Step 2: (2,3-Dihydrobenzofuran-4-yl)methanol

A solution of 2,3-dihydrobenzofuran-4-carboxylic acid (10 g, 61 mmol) in THF (100 mL) was stirred as LAH (4.64 g, 122 mmol) was slowly added. The mixture was heated to reflux for 30 min. The mixture was cooled and quenched cautiously with ethyl acetate and then with 1 N HCI (150 mL). The mixture was then made acidic with 12 N HCI until all the inorganic precipitate dissolved. The organic layer was separated, and the inorganic layer was extracted twice with ethyl acetate. The organic layers were combined, washed twice with brine, and then concentrated in vacuo. This oil was Kϋgelrohr distilled to a clear oil that crystallized upon cooling (8.53 g, 87.6%).

Step 3: 2.3-Dihydrobenzofuran-4-carboxaldehyde

DMSO (8.10 mL, 1 14 mmol) was added at -78°C to a stirred solution of oxalyl chloride in CH2CI2 (40 mL of a 2M solution). A solution of (2,3- dihydrobenzofuran-4-yl)methanol (8.53 g, 56.9 mmol) in CH2CI2 (35 mL) was added dropwise, and the solution stirred at -78°C for 30 min. Triethyl amine (33 mL, 228 mmol) was added cautiously to quench the reaction. The resulting suspension was stirred at room temperature for 30 min and diluted with CH2CI2 (100 mL). The organic layer was washed three times with water, and twice with brine, and then concentrated in vacuo to an oil (8.42 g, 100%) that was used without purification.

Preparation 16

(±)-(trans)-2-(2,3-Dihyd robenzofuran-4-yl)cyclopropane- carboxaldehyde

Step 1 : (±Htrans)-N-Methoxy-N-methyl-2-(2.3-dihydrobenzofuran-4- yhcyclopropanecarboxamide

Trimethylsulfoxonium iodide (9.9 g, 45 mmol) was added in small portions to a suspension of sodium hydride (1 .8 g, 45 mmol) in DMF (120 mL). After the foaming had subsided (10 min), a solution of (trans)- N-methoxy-N-methyl-3-(2,3-dihydrobenzofuran-4-yl)propenamide (3.5 g, 15 mmol) in DMF (60 mL) was added dropwise, with the temperature maintained between 35-40°C. The mixture was stirred for 3 h at room temperature. Saturated NH4CI (50 mL) was added dropwise and the mixture was extracted three times with ethyl acetate. The organic extracts were combined, washed with H2O and brine, dried over K2CO3, and concentrated in vacuo to give a white wax (3.7 g, 100%).

Step 2: (±)-(trans)- 2-(2.3-Dihydrobenzofuran-4-yl)cyclopropane- carboxaldehyde

A solution of (±)-(trans)-N-methoxy-N-methyl-2-(2,3-dihydrobenzofuran- 4-yl)cyclopropanecarboxamide (3.7 g, 15 mmol) in THF (10 mL) was added dropwise to a rapidly stirred suspension of LAH (683 mg, 18 mmol) in THF (50 mL) at -45°C, maintaining the temperature below -40°C throughout. The cooling bath was removed, the reaction was allowed to warm to 5°C, and then the reaction was immediately recooled to -45°C. Potassium hydrogen sulfate (3.4 g, 25.5 mmol) in H20 (50 mL) was cautiously added dropwise, the temperature maintained below – 30°C throughout. The cooling bath was removed and the suspension was stirred at room temperature for 30 min. The mixture was filtered through Celite and the filter cake was washed with ether. The combined filtrates were then washed with cold 1 N HCI, 1 N NaOH, and brine. The filtrates were dried over MgSO4, and concentrated in vacuo to give a clear oil (2.6 g, 99%).

Preparation 18

(-)-(trans)-2-(2.3-Dihydrobenzofuran-4-yl)cyclopropane-carboxaldehyde

Step 1 : (-Htrans)-N-[3-(2.3-Dihvdrobenzofuran-4-yl)-propenoyll-2.10- camphorsultam

To a solution of (-)-2,10-camphorsultam (8.15 g, 37.9 mmol) in 50 mL toluene at 0°C was added sodium hydride (1.67 g, 41.7 mmol). After stirring for 0.33 h at 0°C and 0.5 h at 20°C and recooling to 0°C, a solution of 3-(2,3-dihydrobenzofuran-4-yl)-2-propenoyl chloride

(37.9 mmol), prepared in situ from the corresponding acid and thionyl chloride (75 mL), in toluene (50 mL), was added dropwise. After stirring for 18 h at 20°C, the mixture was diluted with ethyl acetate and washed with water, 1 N HCI, and 1 N NaOH. The organic solution was dried and concentrated in vacuo to give 15.8 g of crude product. Recrystallization form ethanol-methanol (600 mL, 1 :1) gave the product (13.5 g, 92%, mp 199.5-200°C).

(37.9 mmol), prepared in situ from the corresponding acid and thionyl chloride (75 mL), in toluene (50 mL), was added dropwise. After stirring for 18 h at 20°C, the mixture was diluted with ethyl acetate and washed with water, 1 N HCI, and 1 N NaOH. The organic solution was dried and concentrated in vacuo to give 15.8 g of crude product. Recrystallization form ethanol-methanol (600 mL, 1 :1) gave the product (13.5 g, 92%, mp 199.5-200°C).

Step 2: (-)-N-[[(trans)-2-(2,3-Dihydrobenzofuran-4-yl)-cyclopropylj- carbonylj-2, 10-camphorsultam

1 -Methyl-3-nitro-1 -nitrosoguanidine (23.88g 163 mmol) was added in portions to a mixture of 10 N sodium hydroxide (60 mL) and ether (200 mL) at 0°C. The mixture was shaken vigorously for 0.25 h and the ether layer carefully decanted into a solution of (-)-N-[3-(2,3-dihydrobenzofuran-4-yl)-2-propenoyl]-2,10-camphorsultam (9.67 g, 25 mmol) and palladium acetate (35 mg) in methylene chloride (200 mL). After stirring for 18 h, acetic acid (5 mL) was added to the reaction and the mixture stirred for 0.5 h. The mixture was washed with 1 N HCI, 1 N NaOH and brine. The solution was dried, concentrated in vacuo and the residue crystallized twice from ethanol to give the product (6.67 g, 66.5%, mp 157-159°C).

Step 3: (-)-(trans)-2-(2,3-Dihydrobenzofuran-4-yl)cyclopropane- methanol

A solution of (-)-N-[(trans)-2-(2,3-dihydrobenzofuran-4-yl)cyclo-propanecarbonylj-2,10-camphorsultam (4.3 g, 10.7 mmol) in THF (50 mL) was added dropwise to a mixture of LAH (0.81 g, 21.4 mmol) in THF (50 mL) at -45°C. The mixture was stirred for 2 hr while it warmed to 10°C. The mixture was recooled to -40°C and hydrolyzed by the addition of saturated KHS0 (20 mL). The mixture was stirred at room temperature for 30 minutes and filtered. The precipitate was washed twice with acetone. The combined filtrate and acetone washes were concentrated in vacuo. The gummy residue was dissolved in ether, washed with 1 N NaOH and 1 N HCI, and then dried in vacuo to give the product (2.0 g, 98.4%).

Step 4: (-)-(trans)-2-(2.3-Dihydrobenzofuran-4-yl)cyclopropane- carboxaldehyde DMSO (1.6 g, 21 mmol) was added to oxalyl chloride in CH2CI2(7.4 mL of 2 M solution, 14.8 mmole) at -78°C. The (-)-(trans)-2-(2,3-dihydrobenzofuran-4-yl)-cyclopropylmethanol (2.0 g, 10.5 mmol) in CH2CI2(15 mL) was added. The mixture was stirred for 20 min and then triethylamine (4.24 g, 42 mmol) was added. The mixture was warmed to room temperature and stirred for 30 min. The mixture was diluted with CH2CI2 and washed with water, 1 N HCI, and then 1 N NaOH. The organic layer was dried and concentrated iι> vacuo to give the aldehyde product (1.98 g, 100%).

Preparation 24

(-)-(trans)-2-(2.3-Dihydrobenzofuran-4-yl)cyclopropane-methanamine A mixture of (-)-(trans)-2-(2,3-dihydrobenzofuran-4-yl)cyclopropane-carboxaldehyde (1.98 g, 10.5 mmol), hydroxylamine hydrochloride (2.29 g, 33 mmol), and 30% NaOH (3.5 mL, 35 mmol), in 5:1

ethanol/water (50 mL) was heated on a steam bath for 2 h. The solution was concentrated in vacuo. and the residue mixed with water. The mixture was extracted with CH2CI2. The organic extracts were dried and concentrated in vacuo to give a solid which NMR analysis showed to be a mixture of the cis and trans oximes. This material was dissolved in THF (20 mL) and added to solution of alane in THF [prepared from LAH (1.14 g, 30 mmol) and H2S04 (1.47 g, 15 mmol) at 0°Cj. The reaction was stirred for 18 h, and quenched successively with water (1.15 mL), 15% NaOH (1.15 mL), and then water (3.45 mL). The mixture was filtered and the filtrate was concentrated in vacuo. The residue was mixed with ether and washed with water and then 1 N HCI. The acid washes were made basic and extracted with CH2CI . The extracts were dried and concentrated in vacuo to give the amine product (1.4 g, 70.5%). The amine was converted to the fumarate salt in ethanol (mp: 197-198°C).

Anal. Calc’d for C12H15NO • C4H404: C, 62.94; H, 6.27; N, 4.59.

Found: C, 62.87; H, 6.31 ; N, 4.52.

ethanol/water (50 mL) was heated on a steam bath for 2 h. The solution was concentrated in vacuo. and the residue mixed with water. The mixture was extracted with CH2CI2. The organic extracts were dried and concentrated in vacuo to give a solid which NMR analysis showed to be a mixture of the cis and trans oximes. This material was dissolved in THF (20 mL) and added to solution of alane in THF [prepared from LAH (1.14 g, 30 mmol) and H2S04 (1.47 g, 15 mmol) at 0°Cj. The reaction was stirred for 18 h, and quenched successively with water (1.15 mL), 15% NaOH (1.15 mL), and then water (3.45 mL). The mixture was filtered and the filtrate was concentrated in vacuo. The residue was mixed with ether and washed with water and then 1 N HCI. The acid washes were made basic and extracted with CH2CI . The extracts were dried and concentrated in vacuo to give the amine product (1.4 g, 70.5%). The amine was converted to the fumarate salt in ethanol (mp: 197-198°C).

Anal. Calc’d for C12H15NO • C4H404: C, 62.94; H, 6.27; N, 4.59.

Found: C, 62.87; H, 6.31 ; N, 4.52.

FINAL PRODUCT TASIMELTEON

Example 2

(-)-(trans)-N-[[2-(2,3-Dihydrobenzofuran-4-yl)cycloprop-1-yl]methyl]propanamide

This compound was prepared similar to the above procedure using propionyl chloride and (-)-(trans)-2-(2,3-dihydrobenzofuran-4-yl)- cyclopropanemethanamine to give an oil that solidified upon standing to an off-white solid (61 %, mp: 71-72°C). IR (NaCI Film): 3298, 1645, 1548, 1459, 1235 cm“1.

Mo5 : -17.3°

Anal. Calc’d for C15H19N02: C, 73.44; H, 7.87; N, 5.71 . Found: C, 73.28; H, 7.68; N, 5.58.

References

- ‘Time-bending drug’ for jet lag. BBC News. 2 December 2008

- Vachharajani, Nimish N., Yeleswaram, Krishnaswamy, Boulton, David W. (April 2003). “Preclinical pharmacokinetics and metabolism of BMS-214778, a novel melatonin receptor agonist”. Journal of Pharmaceutical Sciences 92 (4): 760–72. doi:10.1002/jps.10348. PMID 12661062.

- Shantha MW Rajaratnam, Mihael H Polymeropoulos, Dennis M Fisher, Thomas Roth, Christin Scott, Gunther Birznieks, Elizabeth B Klerman (2009-02-07). “Melatonin agonist tasimelteon (VEC-162) for transient insomnia after sleep-time shift: two randomised controlled multicentre trials”. The Lancet 373 (9662): 482–491. doi:10.1016/S0140-6736(08)61812-7. PMID 19054552. Retrieved 2010-02-23.

- Audio interview with Joseph Hull of Harvard, spring 2011

- Vanda Pharmaceuticals seeks FDA approval

- Recent progress in the development of agonists and antagonists for melatonin receptors.Zlotos DP.Curr Med Chem. 2012;19(21):3532-49. Review.Vachharajani NN, Yeleswaram K, Boulton DW.J Pharm Sci. 2003 Apr;92(4):760-72.

TASIMELTION

TASIMELTION

PATENTS

| US2010261786 | 10-15-2010 | PREDICTION OF SLEEP PARAMETER AND RESPONSE TO SLEEP-INDUCING COMPOUND BASED ON PER3 VNTR GENOTYPE |

| US2009209638 | 8-21-2009 | TREATMENT FOR DEPRESSIVE DISORDERS |

| US6060506 | 5-10-2000 | Benzopyran derivatives as melatonergic agents |

| US5981571 | 11-10-1999 | Benzodioxa alkylene ethers as melatonergic agents |

| WO9825606 | 6-19-1998 | BENZODIOXOLE, BENZOFURAN, DIHYDROBENZOFURAN, AND BENZODIOXANE MELATONERGIC AGENTS |

| WO2007137244A1 * | May 22, 2007 | Nov 29, 2007 | Gunther Birznieks | Melatonin agonist treatment |

| US4880826 | Jun 25, 1987 | Nov 14, 1989 | Nava Zisapel | Melatonin antagonist |

| US4997845 | May 10, 1990 | Mar 5, 1991 | Eli Lilly And Company | β-alkylmelatonins as ovulation inhibitors |

| US5093352 | May 16, 1990 | Mar 3, 1992 | Whitby Research, Inc. | Antidepressant agents |

| US5151446 | Mar 28, 1991 | Sep 29, 1992 | Northwestern University | Substituted 2-amidotetralins as melatonin agonists and antagonists |

| US5225442 | Jan 3, 1992 | Jul 6, 1993 | Adir Et Compagnie | Compounds having a naphthalene structure |

| US5580878 | Jun 7, 1995 | Dec 3, 1996 | Interneuron Pharmaceuticals, Inc. | Substituted tryptamines phenalkylamines and related compounds |

| US5856529 | Dec 9, 1997 | Jan 5, 1999 | Bristol-Myers Squibb Company | Benzofuran and dihydrobenzofuran melatonergic agents |

| US6211225 | Jun 6, 2000 | Apr 3, 2001 | Bristol-Meyers Squibb | Heterocyclic aminopyrrolidine derivatives as melatonergic agents |

| US7754902 | May 18, 2006 | Jul 13, 2010 | Vanda Pharmaceuticals, Inc. | Ruthenium(II) catalysts for use in stereoselective cyclopropanations |

| US20010047016 | Apr 12, 2001 | Nov 29, 2001 | Gregory Oxenkrug | Method for treating depression |

| US20050164987 | Dec 22, 2004 | Jul 28, 2005 | Barberich Timothy J. | Melatonin combination therapy for improving sleep quality |

| US20090105333 | May 22, 2007 | Apr 23, 2009 | Gunther Birznieks | Melatonin agonist treatment |

extra info

Org. Synth. 1990, 69, 154

(−)-D-2,10-CAMPHORSULTAM

[3H-3a,6-Methano-2,1-benzisothiazole, 4,5,6,7-tetrahydro-8,8-dimethyl-2,2-dioxide, (3aS)-]

|

Submitted by Michael C. Weismiller, James C. Towson, and Franklin A. Davis1.

Checked by David I. Magee and Robert K. Boeckman, Jr..

1. Procedure

(−)-2,10-Camphorsultam. A dry, 2-L, three-necked, round-bottomed flask is equipped with a 1.5-in egg-shaped Teflon stirring bar, a 250-mL addition funnel, and a 300-mL Soxhlet extraction apparatus equipped with a mineral oil bubbler connected to an inert-gas source. The flask is charged with 600 mL of dry tetrahydrofuran (THF) (Note 1) and6.2 g (0.16 mol) of lithium aluminum hydride (Note 2). Into the 50-mL Soxhlet extraction thimble is placed 35.0 g (0.16 mol) of (−)-(camphorsulfonyl)imine (Note 3) and the reaction mixture is stirred and heated at reflux. After all of the(camphorsulfonyl)imine has been siphoned into the reaction flask (3–4 hr), the mixture is allowed to cool to room temperature. The unreacted lithium aluminum hydride is cautiously hydrolyzed by dropwise addition of 200 mL of 1 Nhydrochloric acid via the addition funnel (Note 4). After the hydrolysis is complete the contents of the flask are transferred to a 1-L separatory funnel, the lower, silver-colored aqueous layer is separated, and the upper layer placed in a 1-L Erlenmeyer flask. The aqueous phase is returned to the separatory funnel and washed with methylene chloride (3 × 100 mL). After the reaction flask is rinsed with methylene chloride (50 mL), the organic washings are combined with the THF phase and dried over anhydrous magnesium sulfate for 10–15 min. Filtration through a 300-mL sintered-glass funnel of coarse porosity into a 1-L round-bottomed flask followed by removal of the solvent on arotary evaporator gives 33.5 g (95%) of the crude (−)-2,10-camphorsultam. The crude sultam is placed in a 250-mL Erlenmeyer flask and crystallized from approximately 60 mL of absolute ethanol. The product is collected on a 150-mL sintered-glass funnel of coarse porosity and dried in a vacuum desiccator to give 31.1 g (88%) of the pure sultam. A second crop of crystals can be gained by evaporating approximately half the filtrate; the residue is crystallized as above to give 1.4 g (4%). The combined yield of white crystalline solid, mp 183–184°C, [α]D −30.7° (CHCl3, c 2.3) is92% (Note 5) and (Note 6).

2. Notes

1. Tetrahydrofuran (Aldrich Chemical Company, Inc.) was distilled from sodium benzophenone.

2. Lithium aluminum hydride was purchased from Aldrich Chemical Company, Inc.

3. (−)-(Camphorsulfonyl)imine, [(7S)-(−)-10,10-dimethyl-5-thia-4-azatricyclo[5.2.1.03,7]dec-3-ene 5,5-dioxide] was prepared by the procedure of Towson, Weismiller, Lal, Sheppard, and Davis, Org. Synth., Coll. Vol. VIII, 1993, 104.

4. The addition must be very slow at first (1 drop/5 sec) until the vigorous reaction has subsided.

5. The NMR spectrum of (−)-2,10-camphorsultam is as follows: 1H NMR (CDCl3) δ: 0.94 (s, 3 H, CH3), 1.14 (s, 3 H, CH3), 1.33 (m, 1 H), 1.47 (m,, 1 H), 1.80–2.05 (5 H), 3.09 (d, 1 H, J = 14), 3.14 (d, 1 H, J = 14), 3.43 (m, 1 H), 4.05 (br s, 1 H, NH); 13C NMR (CDCl3) δ: 20.17 (q, CH3), 26.51 (t), 31.55 (t), 35.72 (t), 44.44 (d), 47.15 (s), 50.08 (t), 54.46 (s), 62.48 (d).

6. Checkers obtained material having the same mp (183–184°C) and [α]D − 31.8° (CHCl3, c 2.3).

3. Discussion

(−)-2,10-Camphorsultam was first prepared by the catalytic hydrogenation of (−)-(camphorsulfonyl)imine overRaney nickel.2 Lithium aluminum hydride reduction was used by Oppolzer and co-workers in their synthesis of the sultam.3,4 However, because of the low solubility of the sultam in tetrahydrofuran, a large amount of solvent was required.4 In the procedure described here the amount of solvent is significantly reduced by using a Soxhlet extractor to convey the imine slowly into the reducing medium.5

Oppolzer’s chiral auxiliary,6 (−)-2,10-camphorsultam, is useful in the asymmetric Diels–Alder reaction,3,4 and for the preparation of enantiomerically pure β-substituted carboxylic acids7 and diols,8 in the stereoselective synthesis of Δ2-isoxazolines,9 and in the preparation of N-fluoro-(−)-2,10-camphorsultam, an enantioselective fluorinating reagent.10

References and Notes

- Department of Chemistry, Drexel University, Philadelphia, PA 19104.

- Shriner, R. L.; Shotton, J. A.; Sutherland, H. J. Am. Chem. Soc. 1938, 60, 2794.

- Oppolzer, W.; Chapuis, C.; Bernardinelli, G. Helv. Chim. Acta 1984, 67, 1397.

- Vandewalle, M.; Van der Eycken, J.; Oppolzer, W.; Vullioud, C. Tetrahedron 1986, 42, 4035.

- Davis, F. A.; Towson, J. C.; Weismiller, M. C.; Lal, G.; Carroll,, P. J. J. Am. Chem. Soc. 1988, 110, 8477.

- Oppolzer, W. Tetrahedron 1987, 43, 1969.

- Oppolzer, W.; Mills, R. J.; Pachinger, W.; Stevenson, T. Helv. Chim. Acta 1986, 69, 1542; Oppolzer, W.; Schneider, P. Helv. Chim. Acta 1986, 69, 1817; Oppolzer, W.; Mills, R. J.; Réglier, M. Tetrahedron Lett. 1986, 27, 183; Oppolzer, W.; Poli. G.Tetrahedron Lett. 1986, 27, 4717; Oppolzer, W.; Poli, G.; Starkemann, C.; Bernardinelli, G. Tetrahedron Lett. 1988, 29, 3559.

- Oppolzer, W.; Barras, J-P. Helv. Chim. Acta 1987, 70, 1666.

- Curran, D. P.; Kim, B. H.; Daugherty, J.; Heffner, T. A. Tetrahedron Lett. 1988, 29, 3555.

- Differding, E.; Lang, R. W. Tetrahedron Lett. 1988, 29, 6087.

Org. Synth. 1990, 69, 158

(+)-(2R,8aS)-10-(CAMPHORYLSULFONYL)OXAZIRIDINE

[4H-4A,7-Methanooxazirino[3,2-i][2,1]benzisothiazole, tetrahydro-9,9-dimethyl-, 3,3-dioxide, [4aS-(4aα,7α,8aR*)]]

|

Submitted by James C. Towson, Michael C. Weismiller, G. Sankar Lal, Aurelia C. Sheppard, Anil Kumar, and Franklin A. Davis1.

Checked by David I. Magee and Robert K. Boeckman, Jr..

1. Procedure

A. (+)-(1S)-10-Camphorsulfonamide. Into a 2-L, two-necked, round-bottomed flask, equipped with a 250-mL dropping funnel, a magnetic stirring bar, and a reflux condenser fitted with an outlet connected to a disposable pipettedipped in 2 mL of chloroform in a test tube for monitoring gas evolution, were placed 116 g (0.5 mol) ofcamphorsulfonic acid (Note 1) and 750 mL of reagent-grade chloroform. The suspension of camphorsulfonic acid was heated to reflux and 71.4 g (43.77 mL, 0.6 mol, 1.2 equiv) of freshly distilled thionyl chloride was added dropwise over a 1-hr period. Heating was continued until gas evolution (sulfur dioxide and hydrogen chloride) had ceased (approximately 9–10 hr). The resultant solution of camphorsulfonyl chloride in chloroform was converted tocamphorsulfonamide without further purification.

In a 5-L, two-necked, round-bottomed flask fitted with a 250-mL dropping funnel and a mechanical stirrer was placed a solution of 1.6 L of reagent-grade ammonium hydroxide solution and the flask was cooled to 0°C in an ice bath. The solution of the crude camphorsulfonyl chloride, prepared in the preceding section, was added dropwise to the ammonium hydroxide solution at 0–10°C over a period of 1 hr. The reaction mixture was warmed to room temperature, stirred for 4 hr, the organic layer separated, and the aqueous layer was extracted with methylene chloride (3 × 250 mL). The combined organic layers were washed with brine (250 mL) and dried over anhydrousmagnesium sulfate. Removal of the solvent on the rotary evaporator gave 104.0 g (90%) of the crudecamphorsulfonamide (Note 2) and (Note 3).

B. (−)-(Camphorsulfonyl)imine. A 1-L, round-bottomed flask is equipped with a 2-in. egg-shaped magnetic stirring bar, a Dean–Stark water separator, and a double-walled condenser containing a mineral oil bubbler connected to an inert gas source. Into the flask are placed 5 g of Amberlyst 15 ion-exchange resin (Note 4) and 41.5 g of the crude(+)-(1S)-camphorsulfonamide in 500 mL of toluene. The reaction mixture is heated at reflux for 4 hr. After the reaction flask is cooled, but while it is still warm (40–50°C), 200 mL of methylene chloride is slowly added to dissolve any(camphorsulfonyl)imine that crystallizes. The solution is filtered through a 150-mL sintered glass funnel of coarse porosity an the reaction flask and filter funnel are washed with an additional 75 mL of methylene chloride.

Isolation of the (−)-(camphorsulfonyl)imine is accomplished by removal of the toluene on the rotary evaporator. The resulting solid is recrystallized from absolute ethanol (750 mL) to give white crystals, 34.5–36.4 g (90–95%), mp225–228°C; [α]D −32.7° (CHCl3, c 1.9) (Note 5).