Green Chem., 2016, Advance Article

DOI: 10.1039/C6GC00313C, Communication

DOI: 10.1039/C6GC00313C, Communication

Yu Yang, Sheng Zhang, Lin Tang, Yanbin Hu, Zhenggen Zha, Zhiyong Wang

A water promoted thiolation of indoles with sulfonyl hydrazides has been developed under mild conditions in water.

A water promoted thiolation of indoles with sulfonyl hydrazides has been developed under mild conditions in water.

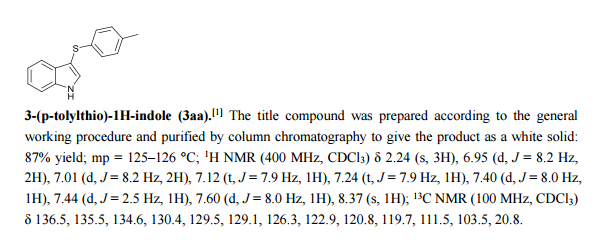

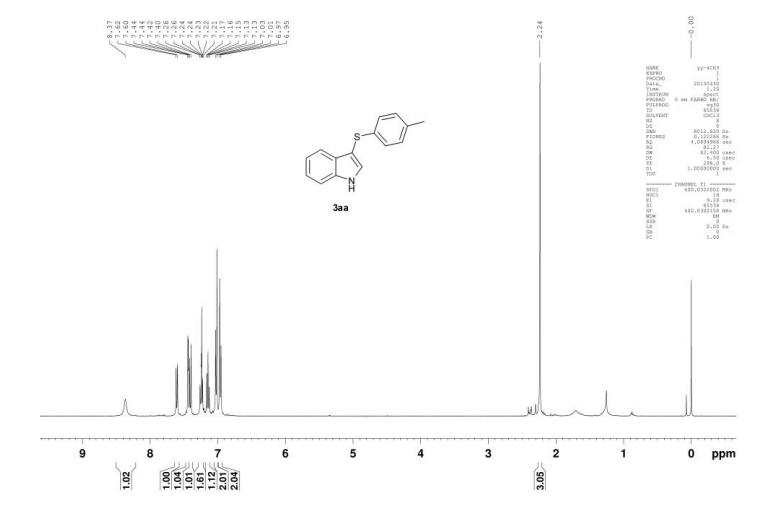

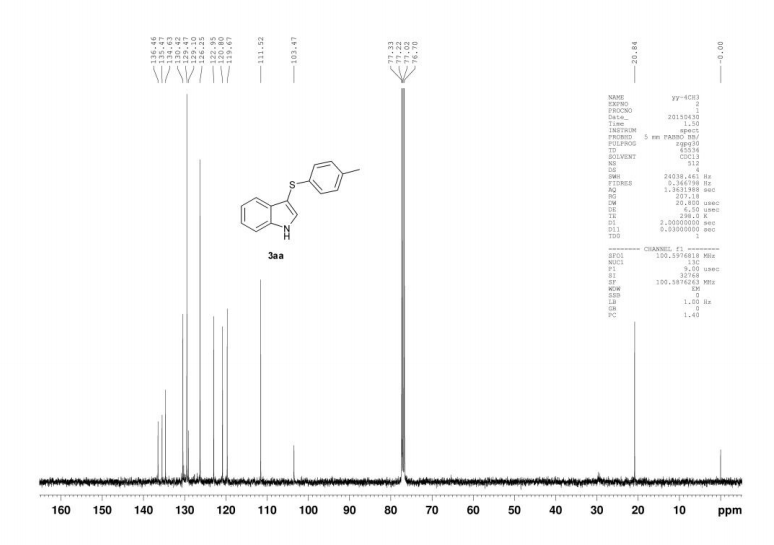

A catalyst-free thiolation of indoles with sulfonyl hydrazides was efficiently developed in water under mild conditions without any ligand or additive. The reaction provided a variety of 3-sulfenylindoles with good to excellent yields and the only by-products were nitrogen and water.

[1] F.-L. Yang, X.-T. Ma and S.-K. Tian, Chem. Eur. J., 2012, 18, 1582

Catalyst-free thiolation of indoles with sulfonyl hydrazides for the synthesis of 3-sulfenylindoles in water

*Corresponding authors

aHefei National Laboratory for Physical Sciences at Microscale, CAS Key Laboratory of Soft Matter Chemistry and Department of Chemistry & Collaborative Innovation Center of Suzhou Nano Science and Technology, University of Science and Technology of China, Hefei, P. R. China

E-mail: zwang3@ustc.edu.cn

Fax: (+86) 551-360-3185

E-mail: zwang3@ustc.edu.cn

Fax: (+86) 551-360-3185

Green Chem., 2016, Advance Article

DOI: 10.1039/C6GC00313C

///////////

.

.