| Synthesis of 5-amino-3-t-butyl-1-(2', 4'-dinitro)phenyl-1Hpyrazole (3) | |||||||||||||||||||||

| A mixture of 4, 4-dimethyl-3-oxo-pentanenitrile (1, 34 mM), 2, 4-dinitrophenyl hydrazine hydrochloride (2, 35 mM) and 50 mL absolute ethanol along with few drops of AcOH were heated at the reflux temperature for overnight and cooled to room temperature. The mixture was evaporated under vacuum and the residue thus obtained was washed with ether, suspended in EtOAc, and treated with 1 M NaOH solution. The organic layer then separated, washed with brine, dried over anhydrous magnesium sulphate and concentrated. The solid which separated was collected, then washed with a mixture of ether and hexane to give 5-amino-3-t-butyl-1-(2', 4'-dinitro)phenyl-1H-pyrazole (3) [22]. | |||||||||||||||||||||

| General procedure for N-[3'-t-butyl-1'-(2", 4"-dinitro) phenylpyrazol-5'-yl] benzamide (5a-l) | |||||||||||||||||||||

| To a solution of 5-amino-3-t-butyl-1-(2', 4'-dinitro)phenyl-1Hpyrazole (3, 9.3 mM) in dichloromethane (5 mL), triethyl amine (23 mM) was added drop wise. The appropriate benzoylchlorides (4a-k, 12 mM) in dichloromethane were added to the above reaction mixture drop wise and stirred for 3 hours at room temperature. The mixture was further diluted with dichloromethane and washed with water, brine followed by once again with water. Sodium sulfate was used to dry the organic layer; solvent was removed under vacuum to get the final derivatives (5a-l). All the compounds were purified over silica to get pure N-(3-tert-butyl-2, 4-dinitro-1-phenyl-1H-pyrazol-5-yl) benzamides (5a-l). | |||||||||||||||||||||

Compound characterization | |||||||||||||||||||||

| N-[3'-t-butyl-1'-(2", 4"-dinitro)phenylpyrazol-5'-yl] benzamide 5a: Yield: 85%, m.p.: 190-192°C, IR (KBr) ν cm-1: 3362 cm-1 (NH str.), 3020 cm-1 (CH str. aromatic), 2950 cm-1 (CH str. methyl), 1643 cm-1 (NH bnd) 1H NMR (CDCl3) δ (ppm): 1.23 (s, 9H, t-butyl), 6.18 (s, 1H, C4, pyrazole), 7.15-7.55 (m, 3H, C3', C4', C5' aromatic), 7.7-7.8 (m, 2H, C5, C6, aromatic), 7.9-8.1 (d, 2H, C2', C6', aromatic), 8.2 (s, 1H, C3, aromatic), 9.61 (bs, 1H, NH amide). ESI-MS (m/z): 410, 100% [M+H]+.

| |||||||||||||||||||||

Organic Synthesis International by Dr Anthony Melvin Crasto Ph.D, Worlddrugtracker, Million hits on google on all sites, One lakh connections worldwide. Pushing boundaries.Interaction site for Organic chemists worldwide, Mail me at amcrasto@gmail.com if you like me

Pages

- Home

- THESIS

- orgsyn.org site

- Chemspider synthetic pages

- ABOUT ME

- DISCLAIMER

- Montelukast and similar drugs

- Glitazar and glitazone series

- ABAN SERIES

- melteon series

- USEFUL LINKS

- LITERATURE SEARCH

- DIPINE SERIES

- International spaces

- GLIPTIN SERIES 2/2

- Atom Economy (AE), Reaction Mass Efficiency (RME) ...

Thursday, 14 January 2016

Design, Synthesis, Antimicrobial and Anti-inflammatory Activity of N-Pyrazolyl Benzamide Derivatives

Sunday, 10 January 2016

Cyclopropanes in water: a diastereoselective synthesis of substituted 2H-chromen-2-one and quinolin-2(1H)-one linked cyclopropanes

Green Chem., 2016, Advance Article

DOI: 10.1039/C5GC02443A, Paper

DOI: 10.1039/C5GC02443A, Paper

Ashish Anand, Jayashree Yenagi, J. Tonannavar, Manohar V. Kulkarni

A one-pot three component reaction has been developed for the synthesis of substituted cyclopropanes employing 4-bromomethyl-2H-chromen-2-one/quinolin-2(1H)-ones, aromatic aldehydes and activated nitriles.

A one-pot three component reaction has been developed for the synthesis of substituted cyclopropanes employing 4-bromomethyl-2H-chromen-2-one/quinolin-2(1H)-ones, aromatic aldehydes and activated nitriles.

A one-pot three component reaction has been developed for the synthesis of substituted cyclopropanes employing 4-bromomethyl-2H-chromen-2-one/quinolin-2(1H)-ones, aromatic aldehydes and activated nitriles. The room temperature reaction in aqueous medium has been found to be diastereoselective and high yielding.

http://pubs.rsc.org/en/Content/ArticleLanding/2016/GC/C5GC02443A?utm_source=feedburner&utm_medium=feed&utm_campaign=Feed%3A+rss%2FGC+%28RSC+-+Green+Chem.+latest+articles%29#!divAbstract

2-(6-Methyl-2-oxo-2H-chromen-4-yl)-3-phenyl-cyclopropane-1,1-dicarbonitrile (4a)

4a, (R= -H, R’= 6-CH3, R”= -CN, X=O)

For a typical compound 4a, (R= -H, R’= 6-CH3, R”= -CN, X=O) IR spectrum showed band at 2246 cm-1 (cyanide) and 1720 cm-1 (lactone). Further, the formation of cyclopropane ring was confirmed by the 1H-NMR wherein the C5-H of coumarin ring resonated at 7.83 ppm as a doublet with 5JC5-H = 1.2 Hz showing a 5-bond coupling with the C4-CH of coumarin ring. C4- CH of coumarin ring appeared at 4.83 ppm as doublet of doublets with Jvic(CH) = 8.8 Hz, Cou-CH 5JC5-H = 1.2 Hz. CH attached to aryl group resonated at 4.61 ppm as a doublet with Jvic(CH) = 8.8 Hz. C6-CH3 protons appeared at 2.45 as a singlet. C3-H was observed as a singlet at 6.82 ppm. Other aromatic protons resonated between 7.68-7.41 ppm. In 13C-NMR, the carbon attached to two cyano group resonated at 15.08 ppm, the methyl carbon appeared at 20.55 ppm. Cyclopropane ring carbon attached to aryl group resonated at 32.81 ppm whereas the one attached to coumarin appeared at 36.78 ppm. Carbon of two cyano group resonated at 112.68 and 112.91 ppm. The lactone carbon of the coumarin ring appeared at 159.35 ppm. Aromatic carbons resonated in the range of 112-159 ppm. Formation of the product was further confirmed by EI-MS where the molecular ion peak was observed at 326 m/z

2-(6-Methyl-2-oxo-2H-chromen-4-yl)-3-phenyl-cyclopropane-1,1-dicarbonitrile (4a) White; Yield 85%;

m.p: 268-270°C;

IR (KBr) cm-1 1720 (C=O lactone), 2246 (CN);

1H-NMR (400 MHz, DMSO-d6, TMS) δ (ppm): 7.83(d, 1H, 5JC5-H = 1.2 Hz, C5-H), 7.68-7.41(m, 7H, ArH), 6.82(s, 1H, C3-H), 4.83(dd, 1H, Jvic(CH) = 8.8Hz, Cou-CH, 5JC5-H = 1.2 Hz), 4.61(d, 1H, Jvic(CH) = 8.8Hz, Ar-CH), 2.45(s, 3H, -CH3);

13C-NMR (100 MHz, DMSO-d6) δ (ppm): 8.57, 15.08, 20.55, 32.81, 36.78, 45.73, 112.68, 112.91, 115.95, 116.69, 117.64, 124.60, 128.62, 129.00,129.12, 130.90, 133.63, 134.23, 146.64, 151.12, 159.35;

MS m/z 326(100%);

Anal Calcd. for C21H14N2O2 (%), Calcd: C, 77.29; H, 4.32; N, 8.58; found: C, 77.26; H, 4.29; N, 8.55

Cyclopropanes in water: a diastereoselective synthesis of substituted 2H-chromen-2-one and quinolin-2(1H)-one linked cyclopropanes

Cyclopropanes in water: a diastereoselective synthesis of substituted 2H-chromen-2-one and quinolin-2(1H)-one linked cyclopropanes

*

Corresponding authors

a

Department of Studies in Chemistry, Karnatak University, Pavate Nagar, Dharwad 580003, India

E-mail: manohar274@gmail.com

E-mail: manohar274@gmail.com

b

Department of Studies in Physics, Karnatak University, Pavate Nagar, Dharwad 580003, India

Green Chem., 2016, Advance Article

DOI: 10.1039/C5GC02443A http://pubs.rsc.org/en/Content/ArticleLanding/2016/GC/C5GC02443A?utm_source=feedburner&utm_medium=feed&utm_campaign=Feed%3A+rss%2FGC+%28RSC+-+Green+Chem.+latest+articles%29#!divAbstract http://www.rsc.org/suppdata/c5/gc/c5gc02443a/c5gc02443a1.pdf ///////////////////////// c1(ccc4c(c1C2[C@@H](C2(C#N)C#N)c3ccccc3)\C=C/C(O4)=O)C

Sunday, 3 January 2016

Palladium(II) porphyrin – anthracene dyad bridged via short and conformationally rigid bicyclo[2.2.2]octadiene spacer

The synthesis and photophysical characterization of a palladium(II) porphyrin – anthracene dyad bridged via short and conformationally rigid bicyclo[2.2.2]octadiene spacer were achieved. A spectroscopic investigation of the prepared molecule in solution has been undertaken to study electronic energy transfer in excited singlet and triplet states between the anthracene and porphyrin units. By using steady-state and time-resolved photoluminescence spectroscopy it was shown that excitation of the singlet excited state of the anthracene leads to energy transfer to the lower-lying singlet state of porphyrin. Alternatively, excitation of the porphyrin followed by intersystem crossing to the triplet state leads to very fast energy transfer to the triplet state of anthracene. The rate of this energy transfer has been determined by transient absorption spectroscopy. Comparative studies of the dynamics of triplet excited states of the dyad and reference palladium octaethylporphyrin (PdOEP) have been performed.

SEE..................

http://pubs.rsc.org/en/content/articlelanding/2015/dt/c5dt03784k#!divAbstract

Paper

Interplay between singlet and triplet excited states in a conformationally locked donor–acceptor dyad

Mikhail A. Filatov,*ab

Fabian Etzold,a

Dominik Gehrig,a

Frédéric Laquai,ac

Dmitri Busko,a

Katharina Landfestera and

Stanislav Baluschevade

*

Corresponding authors

a

Max Planck

Institute for Polymer Research, Ackermannweg 10, D-55128 Mainz, Germany

E-mail: filatovm@tcd.ie

E-mail: filatovm@tcd.ie

b

Institute of

Polymers, Bulgarian Academy of Sciences, Acad. G. Bonchev Str., block

103-A, BG – 1113 Sofia, Bulgaria

c

Physical Sciences

and Engineering Division (PSE), Material Science and Engineering (MSE),

Solar and Photovoltaics Engineering Research Center (SPERC), King

Abdullah University of Science and Technology (KAUST), Thuwal

23955-6900, Kingdom of Saudi Arabia

d

Optics and

Spectroscopy Department, Faculty of Physics, Sofia University “St.

Kliment Ochridski”, 5 James Bourchier, 1164 Sofia, Bulgaria

e

Freiburg Institute

for Advanced Studies (FRIAS), Albert-Ludwigs-Universität Freiburg,

Albertstraße 19, D-79104 Freiburg, Germany

Dalton Trans., 2015,44, 19207-19217

DOI: 10.1039/C5DT03784K

Mikhail A Filatov

Dr.

Marie Curie Postdoctoral Research Fellow

Trinity College Dublin, Dublin · School of Chemistry

Research Experience

- Sep 2015–

presentMarie Curie Postdoctoral Research Fellow

Trinity College Dublin · School of ChemistryIreland · Dublin - Mar 2014–

Sep 2015Research Associate

Institute of Polymers, Bulgarian Academy of SciencesBulgaria · Sofia, Sofia-Capital - Feb 2010–

Mar 2014Postdoctoral researcher

Max Planck Insitute for Polymer ResearchGermany · Mainz - Dec 2008–

Dec 2009Postdoctoral researcher

Institut de Chimie Moléculaire de l'Université de Bourgogne, CNRSFrance · Dijon

Education

- Sep 2000–

Oct 2008Lomonosov Moscow State University

Chemistry · MS and PhDRussia · Moscow

Awards & achievements

- Feb 2015Award: Marie Skłodowska-Curie Individual Fellowship

- Oct 2007Scholarship: • Scholarship of the President of Russian Federation for outstanding PhD students

- Sep 2005Grant: • Grant from the Russian Foundation for Assistance to Small Innovative Enterprises (FASIE) for establishing a start-up company with the innovative project “Development of Technology of 24-Epibrassinolide Production”

Other

- LanguagesBulgarian, English, German, Russian

- Journal

RefereeThe Journal of Organic Chemistry - Other InterestsReading, hiking, diving, traveling

/////////

Saturday, 2 January 2016

Fluoxastrobin

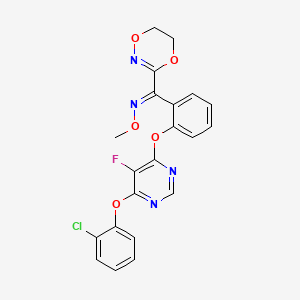

Fluoxastrobin

Fluoxastrobin

Fluoxastrobin; Disarm; Fluoxastrobin [ISO]; UNII-XQ43WY091Y; HEC 480 SC;

(E)-1-[2-[6-(2-chlorophenoxy)-5-fluoropyrimidin-4-yl]oxyphenyl]-1-(5,6-dihydro-1,4,2-dioxazin-3-yl)-N-methoxymethanimine

- (1E)-(2-((6-(2-chlorophenoxy)-5-fluoro-4-pyrimidinyl)oxy)phenyl)(5,6-dihydro-1,4,2-dioxazin-3-yl)methanone O-methyloxime

- 361377-29-9

- 193740-76-0

| Molecular Formula: | C21H16ClFN4O5 |

|---|---|

| Molecular Weight: | 458.826943 g/mol |

103-108 deg C

MacBean

C, ed; e-Pesticide Manual. 15th ed., ver. 5.1, Alton, UK; British Crop

Protection Council. Fluoxastrobin (361377-29-9) (2008-2010)

http://fluoridealert.org/wp-content/pesticides/fluoxastrobin.2004.article.pdf

http://fluoridealert.org/wp-content/pesticides/fluoxastrobin.2004.article.pdf

PAPER

http://pubs.rsc.org/en/content/articlehtml/2015/gc/c5gc00402k

PATENT

US-9193698-B2 / 2015-11-24

Process for preparing fluoxastrobin

(E)-(2-((6-(2-chlorophenoxy)-5-fluoropyrimidin-4-yl)oxy)phenyl)(5,6-dihydro-1,4,2-dioxazin-3-yl)methanone O-methyl oxime [Fluoxastrobin]

To a solution of (E)-(2-((6-chloro-5-fluoropyrimidin-4-yl)oxy)phenyl)(5,6-dihydro-1,4,2-dioxazin-3-yl)methanone O-methyl oxime (14)(100 g, 0.564 mol) in toluene was added 2-chlorophenol (54 g, 0.846 mol), K2CO3 (50

g, 0.733 mol), and DMF (50 mL) at ambient temperature. The reaction

mixture was stirred at 50-60° C. for 3-4 h. The progress of the reaction

was monitored by the HPLC analysis. Upon completion of the reaction,

aqueous NaOH (10%) (200 mL) was charged followed by water (300 mL). The

mixture was stirred and the toluene layer was separated. The toluene layer was washed with a solution of brine (600 mL). The final toluene layer was recovered completely to get the crude product. To the above crude product, methanol

was charged and heated to 60° C. until the clear solution is formed.

The solution was stirred at room temperature to get the pure product

precipitated. The pure fluoxastrobin product was filtered and washed with methanol. The product was further dried to obtain the pure fluoxastrobin product meeting the desired specifications. Yield—75-88%.

IR (cm−1,

KBr) 3072.99w, 2981.58w, 2936.76s, 2819.79w, 2502.01w, 1601.14s,

1572.37s, 1447.88s, 1305.43m, 1268.11m, 1217.15m, 1191.21m, 1092.60m,

1049.05m, 1001.26w, 910.25w, 762.81w.

1H NMR (CDCl3,

400 MHz) δ 3.846 (s, 3H), 4.170-4.160 (t, J=4 Hz, 2H), 4.464-4.484 (t,

J=4 Hz, 2H), 7.261-7.295 (m, 2H), 7.322-7.409 (2, 4H), 8.069 (s, 1H).

13C NMR (CDCl3,

400 MHz) δ 63.103, 64.153, 64.550, 122.659, 123.259, 123.823, 125.712,

127.150, 127.397, 128.094, 130.511, 130.679, 130.776, 131.473, 134.138,

146.004, 148.166, 148.943, 150.354, 150.478, 151.819, 157.395, 157.466,

157.783, 157.854.

MS (EI) m/z 459.1 (M+1); MS2 (EI) m/z 427.1, 383.0,

366.9, 342.1, 306.2, 246.0, 231.1, 188.0.

HPLC (Area %): 99.40%. M.P.

108-112° C.

Isomerisation of (Z)-Fluoxastrobin to (E)-Fluoxastrobin using methane sulphonic acid. To a stirred solution of (Z)-Fluoxastrobin (0.3 g; 0.65 mmole) in acetonitrile (3 ml) was dropwise added methane sulphonic acid

(0.04 ml, 0.65 mmole) at an ambient temperature. The reaction mixture

was stirred for 2-3 hr at the same temperature. The progress of reaction

was monitored by thin layer chromatography (TLC). Dichloromethane

(5 ml) and DM water (5 ml) was added to reaction mass at an ambient

temperature. After vigorous stirring, the layers were separated. The

aqueous layer was back extracted with dichloromethane (5 ml) and the combined dichloromethane layer was washed with 10% aqueous sodium bicarbonate solution (20 ml) followed by washing with 10% brine solution (20 ml). Dichloromethane

was distilled off at reduced pressure at 35-45° C. to obtain

(E)-Fluoxastrobin as crude product (0.25 g, 83% of theoretical yield).

Crude fluoxastrobin on purification in ethanol affords pure (E)-Fluoxastrobin. Isolated product HPLC purity (% area): (Z)-fluoxastrobin: 1.02% and (E)-fluoxastrobin: 95.92%.

Isomerisation of (Z)-Fluoxastrobin to (E)-Fluoxastrobin using phosphoric acid. To a stirred solution of (Z)-Fluoxastrobin (0.25 g; 0.54 mmole) in acetonitrile (4 ml) was dropwise added phosphoric acid

(0.03 g, 0.54 mmole) at an ambient temperature. The reaction mixture

was stirred for 2-3 hr at the same temperature. Progress of reaction was

monitored by thin layer chromatography/HPLC. Dichloromethane

(5 ml) and DM water (5 ml) was added to reaction mass at an ambient

temperature. After vigorous stirring, layers were separated. The aqueous

layer was back extracted with dichloromethane (5 ml). The combined dichloromethane layers were washed with 10% aq. Sodium bicarbonate solution (20 ml) followed by washing with 10% brine solution (20 ml). Dichloromethane

was distilled off at reduced pressure at 40-45° C. to obtained

(E)-Fluoxastrobin (0.22 g, 88% of Theoretical yield). Reaction

monitoring by HPLC (% area): (Z)-Fluoxastrobin: 6.79% and

(E)-Fluoxastrobin: 88.84%. Isolated product HPLC purity (% area):

(Z)-Fluoxastrobin: 6.94% and (E)-Fluoxastrobin: 84.43%.

IR (cm−1,

KBr) 3066.28w, 2981.58w, 2939.36s, 2825.71w, 2500.61w, 1602.36s,

1572.76s, 1441.05s, 1297.05m, 1218.17m, 1116.52s, 1046.15m 1000.86w,

904.73s, 764.71w. 1H NMR (CDCl3, 400 MHz) δ 3.983

(s, 3H), 4.163-4.218 (t, 2H), 4.432-4.440 (t, J=3.2 Hz, 2H), 7.217-7.352

(m, 4H), 7.371-7.390 (m, 2H), 7.483-7.516 (m, 2H), 7.702-7.722 (d, J=8

Hz, 1H), 8.016 (s, 1H). MS (EI) m/z 459.1 (M+1); MS2 (EI) m/z 427.0,

382.9, 366.7, 340.0, 305.8, 246.1, 188.0. HPLC (Area %): 99.11%. M.P.

150-152° C.

Title: Fluoxastrobin

CAS Registry Number: 361377-29-9

CAS Name: (1E)-[2-[[6-(2-Chlorophenoxy)-5-fluoro-4-pyrimidinyl]oxy]phenyl](5,6-dihydro-1,4,2-dioxazin-3-yl)methanone O-methyloxime

Manufacturers' Codes: HEC-5725

Trademarks: Fandango (Bayer CropSci.)

Molecular Formula: C21H16ClFN4O5

Molecular Weight: 458.83

Percent Composition: C 54.97%, H 3.51%, Cl 7.73%, F 4.14%, N 12.21%, O 17.43%

Literature References:

Leaf-systemic broad-spectrum fungicide for use in cereal and food

crops; member of methoxyimiodihydro-dioxazines. Prepn (stereochem.

unspecified): U. Heinemann et al., DE 19602095; eidem, US 6103717 (1997, 2000 both to Bayer). Comprehensive description: S. Dutzmann et al., BCPC Conf. - Pests Dis. 2002, 365. Field trial in winter wheat seeds: I. Haeuser-Hahn et al., BCPC Int. Cong. - Crop Sci. Tech. 2003, 801. Series of articles on chemistry, biology, determn, and environmental fate: Pflanzenschutz-Nachr. Bayer (Engl. Ed.) 57, 299-449 (2004). Ecotoxicology: P. Breuer, ibid. 319.

Properties: White crystals with slight characteristic odor, mp 103-108°. bp 497° (est.). d420 1.422. Log P (octanol/water): 2.86 (20°). Vapor pressure at 20° (extrapolated): 6 ´ 10-10 Pa. Soly at 20° (g/l): n-heptane

0.04; 2-propanol 6.7; xylene 38.1; dichloromethane >250; in water

(mg/l): 2.56 (unbuffered); 2.43 (pH 4); 2.29 (pH 7); 2.27 (pH 9). LD50 in rats, bobwhite quail (mg/kg): >2500, >2000 orally; LC50 (96 hr) rainbow trout, bluegill sunfish, carp (mg/l): 0.44, 0.97, 0.57 (Breuer).

Melting point: mp 103-108°

Boiling point: bp 497° (est.)

Log P: Log P (octanol/water): 2.86 (20°)

Density: d420 1.422

Toxicity data: LD50 in rats, bobwhite quail (mg/kg): >2500, >2000 orally; LC50 (96 hr) rainbow trout, bluegill sunfish, carp (mg/l): 0.44, 0.97, 0.57 (Breuer)

Use: Agricultural fungicide.

MONITORING FLUORINATIONS......Selective direct fluorination for the synthesis of 2-fluoromalonate esters

Optimisation and real time reaction monitoring of the synthesis of 2-fluoromalonate esters by direct fluorination using fluorine gas is reported. An assessment of green metrics including atom economy and process mass intensity factors, demonstrates that the one-step selective direct fluorination process compares very favourably with established multistep processes for the synthesis of fluoromalonates.

Scheme 2 Synthetic routes to 2-fluoromalonate esters.

There are three realistic, low-cost

synthetic strategies available for the large scale manufacture of

diethyl 2-fluoromalonate ester (Scheme 2) which involve reaction of ethanol with hexafluoropropene (HFP), halogen exchange (Halex)and selective direct fluorination

processes. Other syntheses of fluoromalonate esters using electrophilic

fluorinating agents such as Selectfluor™ are possible, but are not

sufficiently commercially attractive to be considered for manufacture on

the large scale.

A growing number of patents

utilising fluoromalonate as a substrate for the synthesis of a range of

biologically active systems have been published

For example, Fluoxastrobin (Fandango®), a fungicide marketed by Bayer

CropScience that has achieved global annual sales of over €140 m since

its launch in 2005, and TAK-733, an anti-cancer drug candidate, employ 2-fluoromalonate esters as the key fluorinated starting material (Scheme 1).

| Scheme 1 2-Fluoromalonate esters used in the synthesis of Fluoxastrobin and TAK-733. | |||||||||||||||||||||

Before a comparison of the green metrics between

the three possible, economically viable large scale processes for the

synthesis of fluoromalonate esters (Scheme 2)

could be carried out, some primary goals for the optimisation of the

process were targeted: complete conversion of the starting material is

essential because it can be difficult to separate the starting material

from the desired monofluorinated product by simple distillation;

fluorine gas usage should be minimised because neutralisation of excess

reagent could potentially generate significant amounts of waste;

reduction in volumes of solvents used to reduce waste streams and

overall intensification of the fluorination process and replacement

and/or reduction of all environmentally harmful solvents used.

Conventional batch direct fluorination

reactions of malonate esters were carried out in glassware vessels by

introduction of fluorine gas, as a 10% or 20% mixture in nitrogen (v/v),

at a prescribed rate via a gas mass flow

controller into a solution of malonate ester and copper nitrate catalyst

in acetonitrile using equipment described previously.

To better understand the relationship between

fluorine gas introduction and rate of conversion, real time IR

spectroscopic monitoring of the reaction was chosen as the most suitable

technique. The use of the ReactIR technique was enabled by a sufficient difference in the carbonyl group stretching frequencies (1734 cm−1 for diethyl malonate and 1775 cm−1 for diethyl 2-fluoromalonate) and provided an in situ reaction profile (Fig. 1).

| Fig. 1 IR spectra of the fluorination reaction at 0% (light blue), 50% (dark blue) and 100% (red) conversions. | ||||||||

The real time reaction monitoring (Fig. 1 and 2)

revealed that the reaction begins instantly upon initiation of fluorine

introduction and the reaction conversion is directly proportional to

the amount of fluorine gas passed into the reaction vessel. When the

intensity of the fluoromalonate carbonyl peak (1775 cm−1) reached a maximum, the introduction of fluorine gas was stopped and the crude reaction mixture was analysed by 1H and 19F

NMR spectroscopy. Complete conversion of the starting material was

observed and diethyl fluoromalonate was formed with 93% selectivity

after introducing 1.1 equivalents of fluorine into the reaction mixture.

The small excess of fluorine explains the unexpectedly small amount of

difluorinated side products B and C

(4.5 and 2.5% respectively) which were the major impurities (6.5 and 9%

respectively) when larger excess of fluorine gas (1.8 eq.) was used.

The effect of concentration of fluorine in

nitrogen, reaction temperature, copper nitrate catalyst loading and

concentration of malonate substrate in acetonitrile were varied to

optimise the fluorination process (Table 1). Additionally, reactions described in Table 1

allowed an assessment of various factors that have a major influence on

the environmental impact of the process such as solvent usage, reaction

temperature and the amount and composition of waste generated. In each

case 20 mmol (3.20 g) of diethyl malonate was used as substrate and the

isolated mass balance of crude material obtained after work-up was

recorded along with the conversion of starting material and yield of

fluorinated products (Table 1).

Table 1 Fluorination of diethyl malonate ester using fluorine gas catalysed by Cu(NO3)2·2.5H2O

| Entry no. | T/°C | C malonate (mol L−1) | Catalyst (mol%) | F 2 in N2 (% v/v) | Conversion (1H NMR) | A/B/C ratio (19F NMR) | Isolated weight |

|---|---|---|---|---|---|---|---|

| 1 | 0–5 | 1.0 | 10 | 10 | 100% | 93.5/4.5/2 | 3.37 g |

| 2 | 0–5 | 1.5 | 10 | 10 | 100% | 94/4/2 | 3.30 g |

| 3 | 0–5 | 1.0 | 5 | 10 | 97% | 95/4/1 | 3.53 g |

| 4 | 0–5 | 1.0 | 2.5 | 10 | 82% | 95/4/1 | 3.51 g |

| 5 | RT | 1.0 | 10 | 10 | 56% | 97.5/1.5/1 | 3.33 g |

| 6 | 0–5 | 1.0 | 10 | 15 | 85% | 97.5/1.5/1 | 3.47 g |

| 7 | 0–5 | 1.0 | 10 | 20 | 100% | 94/3/3 | 3.50 g |

| 8 | 0–5 | 2.0 | 5 | 20 | 52% | 92/5/3 | 3.40 g |

In all cases, small quantities of side products were formed which were identified by 19F

NMR and these originate from two different processes:

3,3-difluoromalonate is produced from enolisation of diethyl

fluoromalonate which is much slower than enolisation of the diethyl

malonate substrate, while the fluoroethyl fluoromalonate is postulated

to form via an electrophilic process.

The data in Table 1

suggest that the concentration of the malonate ester substrate in

acetonitrile has no apparent effect on the outcome of the reaction

although solvent is required for these reactions because diethyl

malonate does not dissolve the catalyst. Additionally, the use of high

dielectric constant media, such as acetonitrile, have been found to be

beneficial for the control of selectivity of electrophilic direct

fluorination processes.

For convenience, a 1.5 M concentration of malonate in acetonitrile was

chosen as the optimal conditions which is approximately 5 mL solvent per

1 mL of diethyl malonate.

The concentration of fluorine gas, between

10–20% v/v in nitrogen, does not affect the selectivity of the reaction

and the quality of the product either, as exemplified by the product

mixtures obtained from reactions 1, 2 and 7 which have identical

compositions. In contrast, carrying out fluorination reactions at room

temperature rather than cooling the reaction mixture to 0–5 °C leads to

increased catalyst decomposition which results in an insoluble copper

species that on occasion blocked the fluorine gas inlet tube. In

addition, without cooling, the exothermic nature of this fluorination

reaction led to a slight reaction temperature increase (from 20 to 29 °C

in a small scale laboratory experiment) resulting in loss of some

solvent and some decomposition of the catalyst and product degradation.

Lowering the concentration of the copper

nitrate catalyst led to a significantly slower reaction as would be

expected and required the use of a larger excess of fluorine gas to

enable sufficiently high conversion. For example, the reaction proceeded

in the presence of only 2.5 mol% catalyst, but in this case 40% excess

fluorine was required to reach 100% conversion.

Typical literature work-up procedures for direct fluorination reactions

involve pouring the reaction mixture into 3 to 5 volumes of water and

extracting the resulting mixture three times with dichloromethane. The

combined organic fraction is typically washed with water, saturated

sodium bicarbonate solution and dried over sodium sulfate before

evaporation of the solvent to give the crude reaction product. We sought

to improve the work-up to enable recycling of the reaction solvent and

substitute the use of environmentally harmful dichloromethane in the

reaction work-up stage. Upon completion of fluorine gas addition,

acetonitrile was evaporated for reuse and then the residue was

partitioned between ethyl acetate and water, the organic phase was

washed with water, saturated Na2CO3

solution and saturated brine and dried prior to evaporation under

reduced pressure. Modification of the workup procedure in this manner

enables the recovery of acetonitrile and ethyl acetate and significantly

reduces the amount of aqueous waste generated. When direct reuse of the

recovered acetonitrile was attempted, a copper containing precipitate

was formed presumably because of the high HF content of the solvent

(0.63 M by titration). Therefore, before reuse of the solvent, HF must

be removed. Stirring the recovered reaction solvent with solid Na2CO3

lowered the acid content to an acceptable level (0.04 M) and when a

second fluorination reaction was carried out in the recovered,

neutralised acetonitrile, no change in the fluorination reaction profile

was observed.

Upon completion of these optimisation

studies, selective fluorination reactions of malonate esters were scaled

up to 40 g scale in the laboratory without experiencing any change in

product profile. Isolation of significant quantities of

monofluoromalonate A crude product (99% yield, 95%

purity) was achieved which could be used in the subsequent cyclisation

processes described below without further purification or, if high

purity material was required, could be purified by fractional vacuum

distillation (bp. 102–103 °C, 18 mbar) to produce 99% pure material in

77% yield.

Related malonate esters were also subjected

to direct fluorination using the optimised conditions established above.

In the case of di-tert-butyl malonate,

fluorination was carried out on 12 g scale. 100% conversion was reached

after the introduction of 1.2 equivalents of fluorine gas and the

desired product was isolated in 96% yield. The purity of the crude

product was higher than 97% by 1H and 19F

NMR spectroscopy without any further purification and as expected, the

only side product was the 2,2-difluorinated product (Scheme 3).

| Scheme 3 Fluorination of di-methyl and di-tert-butyl malonates. | ||

Diethyl fluoromalonate large scale fluorination

Diethyl malonate (40.0 g, 0.25 mol) and copper nitrate hydrate (Cu(NO3)2·2.5H2O; 5.81 g, 25 mmol) were dissolved in acetonitrile (200 mL) and placed in 500 mL fluorination vessel, cooled to 0–5 °C and stirred at 650 rpm using an overhead stirrer. After purging the system with N2 for 5 minutes, fluorine gas (20% v/v in N2, 80 mL min−1, 265 mmol) was introduced into the mixture for 6 hours and 30 minutes. The reactor was purged with nitrogen for 10 minutes, the solvent removed in vacuo and the residue partitioned between water (50 mL) and ethyl acetate (50 mL). The aqueous phase was extracted once more with ethyl acetate (50 mL) and the combined organic layers were washed with saturated NaHCO3 (25 mL) and brine (20 mL). After drying over sodium sulfate, the solvent was evaporated to leave diethyl 2-fluoromalonate (44.4 g, 99% yield, 95% purity) as a light yellow, transparent liquid. This crude product was distilled to afford high purity fluoromalonate (34.7 g, 77% yield, 99%+ purity) as a colourless liquid, bp. 102–103 °C (18 mbar), (lit.: 110–112 °C, 29 mbar), spectroscopic data as above.........N. Ishikawa, A. Takaoka and M. K. Ibrahim, J. Fluorine Chem., 1984, 25, 203–212 CrossRef CAS.

PAPER

REF

DOI: 10.1039/C5GC00402K

(Paper)

Green Chem., 2015, 17, 3000-3009

Fluorine gas for life science syntheses: green metrics to assess selective direct fluorination for the synthesis of 2-fluoromalonate esters†

Antal

Harsanyi

and

Graham

Sandford

*

Department of Chemistry, Durham University, South Road, Durham, DH1 3LE, UK. E-mail: graham.sandford@durham.ac.uk

Department of Chemistry, Durham University, South Road, Durham, DH1 3LE, UK. E-mail: graham.sandford@durham.ac.uk

Received

19th February 2015

, Accepted 17th March 2015

First published on the web 17th March 2015

Optimisation

and real time reaction monitoring of the synthesis of 2-fluoromalonate

esters by direct fluorination using fluorine gas is reported. An

assessment of green metrics including atom economy and process mass

intensity factors, demonstrates that the one-step selective direct

fluorination process compares very favourably with established multistep

processes for the synthesis of fluoromalonates.

Paper

Fluorine gas for life science syntheses: green metrics to assess selective direct fluorination for the synthesis of 2-fluoromalonate esters

Antal Harsanyia and

Graham Sandford*a

*Corresponding authors

aDepartment of Chemistry, Durham University, South Road, Durham, UK

E-mail: graham.sandford@durham.ac.uk

E-mail: graham.sandford@durham.ac.uk

Green Chem., 2015,17, 3000-3009

DOI: 10.1039/C5GC00402K

Subscribe to:

Comments (Atom)